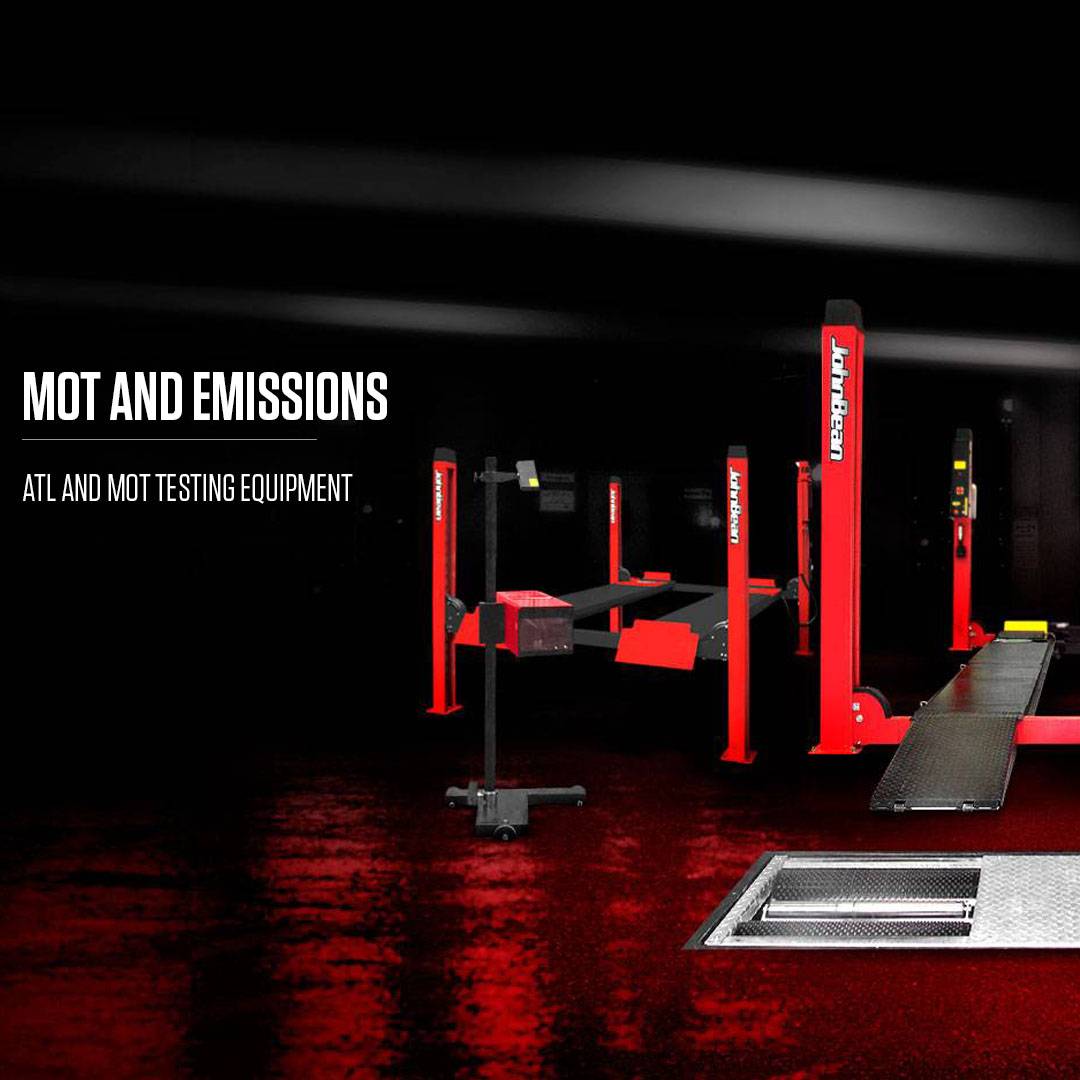

MOT AND EMISSIONS

ATL AND MOT TESTING EQUIPMENT

ATL AND MOT TESTING EQUIPMENT

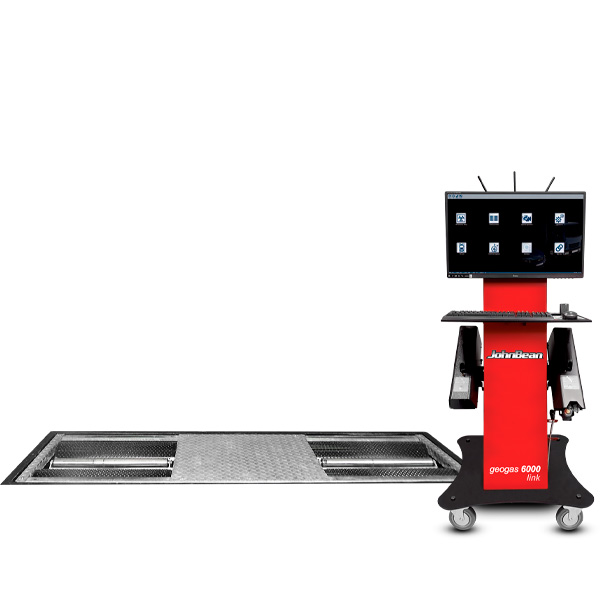

Branch out to MOT testing, upgrade to one-person testing operation or grow your output with an automated test lane with John Bean®.

If you are considering becoming a DVSA approved testing station, or if you just want to renew some equipment in your existing bay, John Bean has a fully integrated service that will support you through all the procedures and legislation requirements.

The team based in our UK headquarters will help you through the whole process: from choosing the most suitable equipment kit to installation.

Once the equipment is installed and your ATL/MOT bay is up and running, we can provide unrivalled product support with over-the-telephone assistance from our dedicated team.

Our network of UKAS and GEA accredited engineers is on hand to provide calibration and routine maintenance services to keep your investment in the best working condition.

Our experienced and dedicated team means the John Bean brand has an unparalleled reputation for providing the highest quality, excellent value and great service.

CLASS IV AND CLASS VII, 4 POST AND CAR SCISSOR LIFT OPTIONS

BE FAST

CLASS IV LOW PROFILE, CLASS IV STANDARD, CLASS VII STANDARD

BE FAST

BENEFITS

As an automotive repair professional, you already know that the key to building a successful business is equal parts customer service and revenue generation. Wheel alignment machines allow you to offer a necessary service to your customer that will keep their newly purchased tyres from wearing unevenly and reduce extra stress on their car or truck’s suspension components. Offering this full-service experience will maximise customer satisfaction by offering a one-stop-shop that saves your customers precious time. Not only will this level of service ensure that they return to your shop in the future but it will also ensure that they refer their friends and family as well. Beyond building a base of loyal customers, keeping wheel alignment services in-house also allows you to diversify your revenue stream for the long haul. Whether you run a high-volume tyre shop or you’re a smaller, local mechanic; John Bean has a machine for your needs.

Modern Vehicles Need Modern Solutions

Today’s modern, fuel-efficient cars, trucks, and SUVs utilize a variety of advanced suspension designs and autonomous safety technologies to provide modern vehicles with a stable, secure driving experience. Performing a 4 wheel alignment for your customers ensures that the vehicle’s front and rear axles are perfectly aligned. This is important because vehicles out of alignment will suffer from additional suspension wear, premature tire wear, and be more challenging to drive. Performing 4 wheel alignment services bring a unique challenge to the table for shop owners since the machines and time required to run these machines can often be a huge challenge for shop owners and managers. High Volume and Quick Alignment Times = Shop Revenue and John Bean machines are up to this task.

Space Limitations

One of the biggest challenges with integrating a wheel aligner into your shop is crucial shop floor space. Every piece of equipment on your shop’s floor is meant to service your customers and bring in revenue. Wheel alignment machines are traditionally large machines that require an alignment lift, console, and sensors to perform their duties but modern technology has allowed wheel aligners to remain incredibly accurate while drastically shrinking in size. Thanks to advances like imaging 3D technology, John Bean alignment equipment is more compact and accurate than ever. Most of our models are also highly mobile, which means that you have the option to roll the wheel alignment equipment away when it’s not in use.

Additional Services = More Revenue

A John Bean wheel alignment machine allows you to capture more revenue and increase job profitability by offering more services to your customers that take less time to complete. By utilizing the integrated audit check function, you can check the alignment on every vehicle that comes into the shop and present the results to the customer, making an upsell easier. Wheel alignment goes hand in hand with new tires and is part of the maintenance regimen for modern vehicles. Much like offering oil changes at your shop, offering wheel alignment ensures that your shop can perform a variety of high-revenue, repeatable services, along with one-off opportunities as well. Modern wheel aligners like those offered by John Bean allow your team to quickly perform alignment services so you can get more cars on the rack and make more money.

A Wide Range Of Models For A Wide Range Of Needs

Whether you’re looking for a high-level, drive-through style machine with automatic lift tracking, or a more compact, wireless design that’s perfect for a shop with limited floor space; John Bean has a machine that will fit your needs. We know that not every shop has the same needs or the same budget and that’s why we’ve developed a range of wheel alignment machines to meet the diverse needs of automotive service professionals. Even though we pioneered this technology, we never rest on our laurels and continually offer new, more advanced technologies for your automotive needs.

FAQs

Modern vehicles require regular alignments to minimize tire/suspension wear, and to maintain an overall safe, secure driving experience. Quality wheel alignment machines perform alignments quickly and efficiently so you can enjoy an additional, sustainable, repeating revenue source for your shop that leads to higher levels of customer satisfaction and repeat business.

There are a variety of alignment machines available to meet the unique needs of every shop. To properly equip your shop with the right wheel alignment machine, you’ll want to consider the following:

- How much space do you have for an alignment machine?

- What types of vehicles do you typically work on (consumer, heavy-duty commercial, emergency, etc.)?

- What level of training and skill level do your technicians have?

- What type of return on investment are you looking for?

- What features are the most important to you and your technicians?

One of the most important features of modern vehicles is the inclusion of Advanced Driver Assistance Systems (ADAS) like lane keeping assist and emergency braking. ADAS systems rely on sensors, cameras, and other devices to maintain vehicle position in response to driver inputs. Without proper wheel alignment, ADAS systems may not react or may over react, leaving drivers at risk.

No one knows a vehicle better than the manufacturer who made it. OEM (Original Equipment Manufacturer) approval means that a wheel alignment machine has been certified by the vehicle manufacturer to properly measure their unique vehicles to a certain level of accuracy. This third party approval ensures that the wheel alignment machine meets certain stringent requirements.

Absolutely! The alignment surface must be completely level because the machine is going to measure the caster, camber, and toe of each wheel. An uneven surface will falsely indicate the position of a wheel and the machine will indicate the need for an over correction or under correction that will lead to issues once the vehicle is out on the road.

While Caster may not be directly responsible for tire wear, it does have an effect on the overall driving feel. If the camber is not adjusted properly, the inside of the tire or outside of the tire can wear prematurely but this is typically a slow process. If the toe is off, there are very few indications (pulling, wandering, etc.) of being out of alignment but tire wear can happen very quickly. A comprehensive alignment will ensure even tire wear by properly setting the caster, camber, and toe to their factory recommended specifications.

Proper wheel alignment is always started in the rear. A properly aligned geometric centerline needs to be established (starting at the rear of the vehicle and moving forward) prior to performing any other adjustments on the wheels. This is known as thrust. All other adjustments will require that the thrust is properly adjusted, otherwise, it can throw off the other measurements and lead to an improperly aligned vehicle.