V4400 Wireless Drive-Through Wheel Alignment System

The V4400 Commander® from John Bean® redefines wheel alignment with advanced wireless technology and intelligent design. Built for modern workshops, it delivers faster setup, greater accuracy, and superior flexibility — all while reducing bay downtime and maximising efficiency.

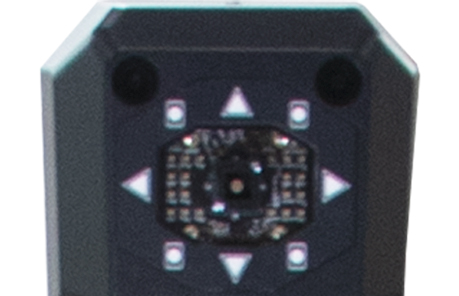

Featuring a dual-tower system with high-resolution cameras, the V4400 provides a stable, comprehensive field of view without the need for a cross-view camera or fixed line of sight between towers. This forward-thinking configuration supports a wide range of vehicle lengths and bay setups, including full drive-through capability.

When ADAS-equipped vehicles are detected, the system automatically provides the correct adjustment and target placement steps to ensure precise results every time.

Designed for versatility, the system delivers accurate alignment for vehicles from compact cars to light commercial models up to 9 metres long. Installation options adapt easily to any workshop layout, ensuring maximum efficiency and precision across every alignment.

Features

Drive-Through Design

The dual-tower design can accommodate larger-width vehicles by allowing the technician to position the towers apart at optimal distances. This also leaves space at the front of the vehicle to perform other tasks such as ADAS recalibration.

D2 Max® Technology

Our all-new D2 Max® Technology achieves a more precise, real-world alignment reading by mapping and projecting the vehicle’s drive direction as if on the road. This revolutionary advancement in wheel alignment delivers unparalleled accuracy and repeatability, reducing initial test drive issues and future comebacks.

Adjustable Camera Post

The alignment towers have adjustable camera posts with two cameras per side, providing a wider field of view. The post offers two locking points for accurate, stable camera positioning and transitions between the fully raised and fully lowered positions without requiring intermediate heights or additional tracking mechanisms.

VIDEO: SEE IT IN ACTION

ADDITIONAL FEATURES

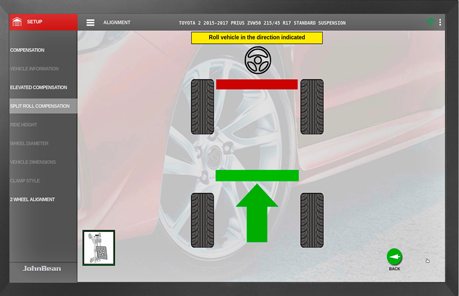

Fast Compensation and Optimised Alignment Flow

Streamline workflow with fast measurement compensation and an optimised alignment flow that enhances productivity by eliminating unnecessary steps in the alignment process.

Advanced Notification System

The advanced notification system provides critical information without slowing down the alignment process, automatically detecting and compensating suspension stress issues or environmental errors, only notifying the technician when necessary to provide additional information for corrective action.

Audit Mode

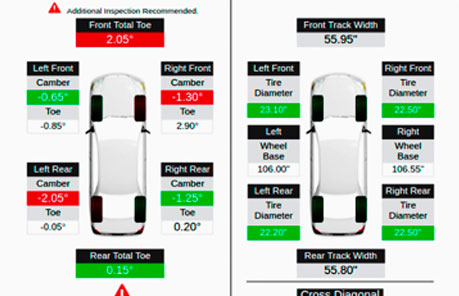

Quickly uncover extra service opportunities with alignment audit reports. This report includes measurement of track width, front and rear toe, camber, wheelbase, wheel diameter, and cross dimensions.

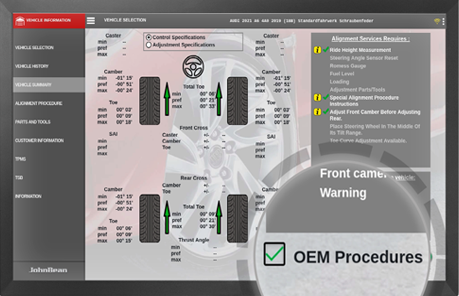

OEM Aftermarket Procedures

The software provides the OEM recommended workflow for accurate wheel alignment in the aftermarket segment.

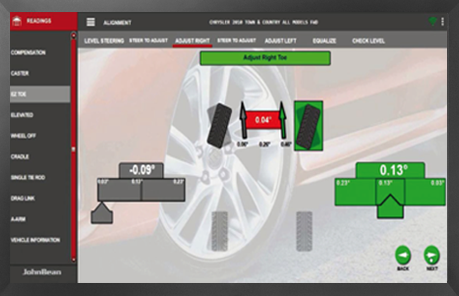

EZ-TOE

Our advanced software makes it easy to quickly and accurately measure toe angle, allowing technicians to turn the wheel to access challenging adjustment points without using a steering wheel holder.

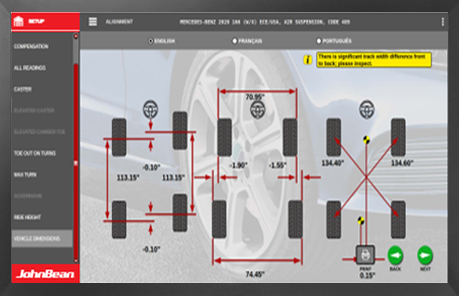

Advanced Dimensions

Advanced vehicle dimensioning, including Cross Dimensions measurements to identify frame or structural damage before alignment adjustments are made, and Wheel Diameter to identify mismatched tyre sizes, a potential cause of vehicle pulling and drive train damage.

Cloud Services

Easily share service reports with your customers via email or print from anywhere in the shop.

Target Imaging Pointer (TIP)

The target imaging pointer (TIP) measures ride height more accurately than manual measuring to obtain proper alignment specifications.

VODI™

Our exclusive Vehicle Orientation Directional Indicator, VODI™, guides the technician through the measurement process, reducing the time spent walking back and forth from the vehicle to the aligner.

Mobility Kit

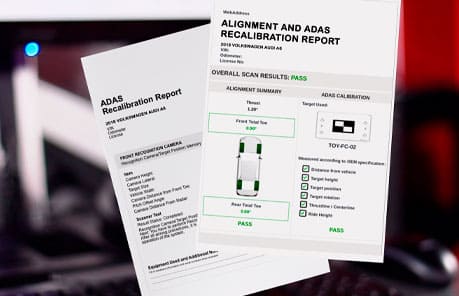

ALIGNMENT REPORT

Print full-colour before-and-after reports for your customers, showing completed corrective actions and clearly demonstrating the benefits of wheel alignment.

ADJUSTMENTS

- EZ-Toe

- A-Arm

- Cradle

- Single Tie Rod

- Drag Link

- Toe Curve

- Elevated

- Help Videos

- Parts Calculator

- Parts & Tools

- Wheels Off

MEASUREMENTS

- SAI

- Max Turn

- Toe Out On Turns

- ROMESS - OPTIONAL

- TIP Target Ride Height

- Frame Angle

- On-Demand Ride Height

TECH SPECS

Tyre Diameter (AC400)

19″-39″ | 50-100cm

Wheel Diameter (AC200)

12″-24″ | 30-60cm

Track Width

48″-96″ | 120-245cm

Wheelbase

79″-200″ | 200-500cm

Power Supply

110-240V 50/60Hz

Camera Working Width from Lift Centerline

40″-70″ | 102-178cm

Optimal Width from Lift Centerline

50″-60″ | 127-152cm

Turntable to Tower Working Range

55″-200″ | 140-508cm

Optimal Range

85″-115″ | 216-292cm

ACCESSORIES

STANDARD

OPTIONAL