OEM TRUSTED EQUIPMENT: TESLA | VOLVO

V2380 Imaging Diagnostic Wheel Alignment System

The John Bean® V2380 wheel aligner combines a classic post-and-beam design with productivity‑boosting technology to help shops perform efficient, accurate wheel alignment services. Designed for fast-paced workshops, it delivers precise results without slowing down critical alignment procedures.

Fast compensation and an optimised alignment workflow allow technicians to work quickly and accurately, while an advanced notification system instantly alerts them to suspension stress or potential errors. These smart features help technicians move smoothly through each alignment step with minimal interruption.

Additional productivity-enhancing features, including automatic camera tracking, EZ-Toe, and exclusive AC400 non-contact wheel clamps, reduce setup time and simplify adjustments. Together, these tools support higher throughput and consistent alignment accuracy across a wide range of vehicles.

VERSIONS

V2380 Lift (EEWAEU545TB4)

Features

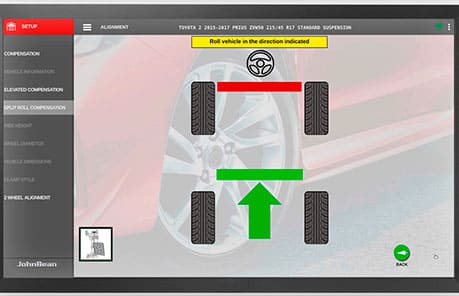

FAST COMPENSATION AND OPTIMISED ALIGNMENT FLOW

Streamline workflow with fast measurement compensation and an optimised alignment flow that enhances productivity by eliminating unnecessary steps in the alignment process.

Automatic camera tracking eliminates the need to readjust the camera after raising the lift, while a continuously calibrating third camera retains ultimate accuracy.

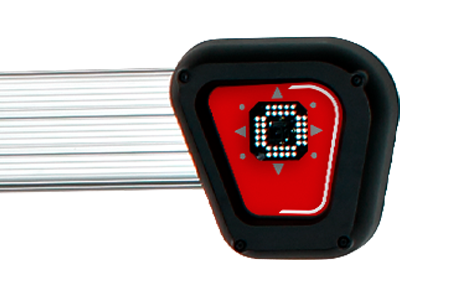

VODI™

Our exclusive Vehicle Orientation Directional Indicator, VODI™, guides the technician through the measurement process, reducing the time spent walking back and forth from the vehicle to the aligner.

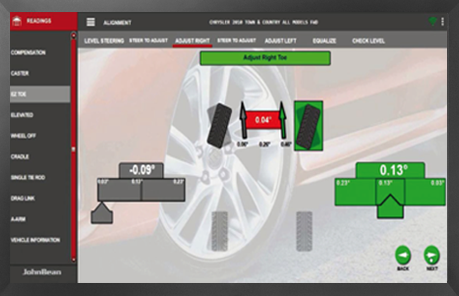

EZ-TOE

CLOUD SERVICES

Easily share service reports with your customers via email or print from anywhere in the workshop.

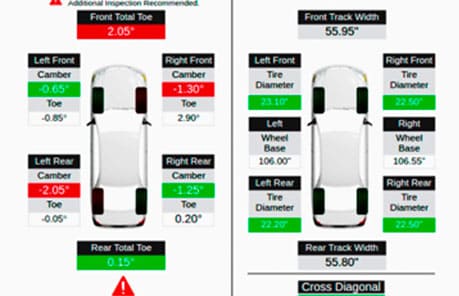

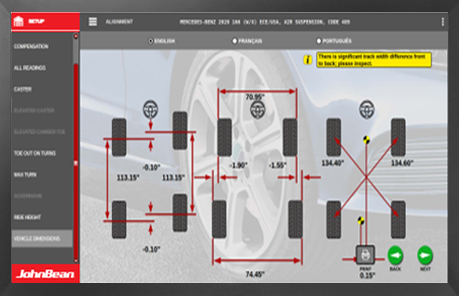

ADVANCED VEHICLE DIMENSIONS

Including cross dimensions measurements to identify frame or structural damage before alignment adjustments are made, and Wheel Diameter to identify mismatched tyre sizes, a potential cause of vehicle pulling and drive train damage.

ADDITIONAL FEATURES

RIDE HEIGHT

Eliminate manual data entry, speed up measuring, and increase accuracy using our specially designed, optional Ride Height Targets.

The optional kit allows you to mount the cross-beam to the cabinet for flexible installation and usage, enabling you to move the system around the shop freely and out of the way as needed.

AC400 CLAMPS

The clamp attaches to the tire with optimal force without touching the rim; ensuring a safe, fast, and consistent clamping experience.

AC200 CLAMPS

Optional AC200 Wheel Clamps are fast and easy to use with self-centering design, two-sided claws provide reliable clamping, even over hub caps.

ADJUSTMENTS

- EZ-Toe

- A-Arm

- Cradle

- Single Tie Rod

- Drag Link

- Toe Curve

- Elevated

- Help Videos

- Parts Calculator

- Parts & Tools

- Wheels Off

MEASUREMENTS

- SAI

- Max Turn

- Toe Out On Turns

- Manual Ride Height

- TIP Target Ride Height

- Frame Angle

- ROMESS - OPTIONAL

- On-Demand Ride Height

TECH SPECS

Part Number

EEWAEU545TB4 – V2380 Lift

Tyre Diameter (AC400)

19″-39″ | 48-99cm

Wheel Diameter (AC200)

12″-24″ | 30-61cm

Track Width

48″-96″ | 122-244cm

Wheelbase

79″-180″ | 201-457cm

Power Supply

110-240V 50/60Hz

Camera System

2 cameras, 5.1. Mega Pixel

Software

Custom UI and OS

Track Width

121.9 cm – 243.8 cm (48” – 96”)

Wheel Base

200.7 cm – 457.2 cm (79” – 180”)

Shipping Weight

227 kg (501 lbs)

Power Requirements

100–230 Volts AC, 50/60Hz, 15 Amps circuit. Must have earth ground.

Agency Approvals

UL201, C22.2, CE

ACCESSORIES

STANDARD

OPTIONAL