John Bean Wheel Alignment

Magnified Readings, Projected for Clarity

Precision crosshair targets displayed caster, camber, and toe measurements at a glance. Magnified readings projected onto a large screen allowed both operator and customer to clearly see the results—eliminating guesswork. The Visualiner® enabled quick, accurate checks, and simplified adjustments by allowing real-time visibility of corrections as they were made.

Remote Access, Real-Time Results

An all-new Remote-Control Unit came standard on the 1955 Visualiner® and was also offered as a convenient upgrade kit for earlier models. Introduced just a few years after the first light-based Visualiner® systems debuted, this innovation gave technicians fingertip control of alignment charts from beneath the vehicle, eliminating time wasted walking back and forth. By streamlining adjustments and reducing unnecessary steps, the Remote-Control Unit helped drive faster alignments and greater shop productivity.

Photo #1263 (Mechanical Aligner): This photo captures an early mechanical aligner from John Bean-FMC, taken in the 1930s at their Lansing, Michigan engineering labs. A key contributor to the development of alignment systems, it paved the way for the Visualiner® and the modern computerized Visualiner® II, revolutionizing optical alignment technology.

Photo #1265 (Wheel Balancer): This vintage image features the original Model 555 Wheel Balancer from John Bean-FMC, introduced in the 1930s. It was a cutting-edge tool at the time, designed to balance wheels and included convenient storage trays for weights, marking it as a pioneer in wheel service technology.

The Ingenious Dr. Bernie Jackson: From Apollo to the V3D Aligner

Dr. Bernie Jackson, an engineer and entrepreneur, entered the wheel alignment industry with an astonishing background. His career began in astrophysics, contributing to the Apollo moon landing, where he designed the camera used during the mission. Afterward, Jackson turned his attention to creating the first generation of flight simulators—not the gaming systems we know today, but complex training systems used by pilots. His company thrived, but Jackson, always seeking new challenges, sold it and asked himself, “What’s next?”

One day, while driving behind a vehicle with obvious dog-tracking and camber issues, Dr. Bernie Jackson had a flash of inspiration: “If I can see with my own eyes that this car needs alignment, I could use a camera and computer to calculate exactly how to adjust the wheels.” Drawing from his deep expertise in imaging systems and his work on 3D spatial calculations for the Apollo project, Jackson envisioned using a camera-based system to simplify and enhance alignment accuracy. He gathered a team of top experts in cameras, optics, and computer processing from Silicon Valley, where these technologies converged.

His approach revolutionized the alignment industry. Jackson created the first camera-target-based aligner, marking a seismic shift in how wheel alignment was performed. Recognizing the value of his work, Snap-on acquired both Jackson’s company and his patents just as they were expanding the John Bean brand. This perfect convergence of timing and innovation ensured that Snap-on could leverage Jackson’s 3D technology to stay ahead of the competition. As a result, for the next 20 years, many Snap-on competitors licensed Jackson’s 3D camera-based alignment patents.

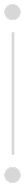

Spindle Pivot

Purpose: Represents the point at which the suspension pivots during steering.

Adjustment: Fixed location. Used to identify suspension geometry and vehicle thrust angle; may also be referenced during damage analysis.

Anchor Point

Purpose: Indicates where the structure of the frame is attached to the suspension or vehicle body.

Adjustment: Fixed. Used to assess structural damage or misalignment during repair or realignment.

Cowl Mount

Purpose: Used to locate upper suspension mounting points. May also indicate shock tower or cowl panel.

Adjustment: Fixed sheet metal. May sag or move slightly due to collision damage.

Centerline

Purpose: Indicates the centerline of the wheel assembly and marks the wheel’s lateral position. This reference may vary slightly side-to-side.

Adjustment: Fixed within the suspension system. Primarily used for measurement and to verify lateral symmetry between the left and right wheels.

Anchor Point

Purpose: Same as the frame anchor point on the left side.

Adjustment: Fixed. Used as a reference for locating suspension and steering components during pushing or alignment.

Spindle Pivot

Purpose: Represents the point at which the suspension pivots during steering.

Adjustment: Fixed location. Used to identify suspension geometry and vehicle thrust angle; may also be referenced during damage analysis.

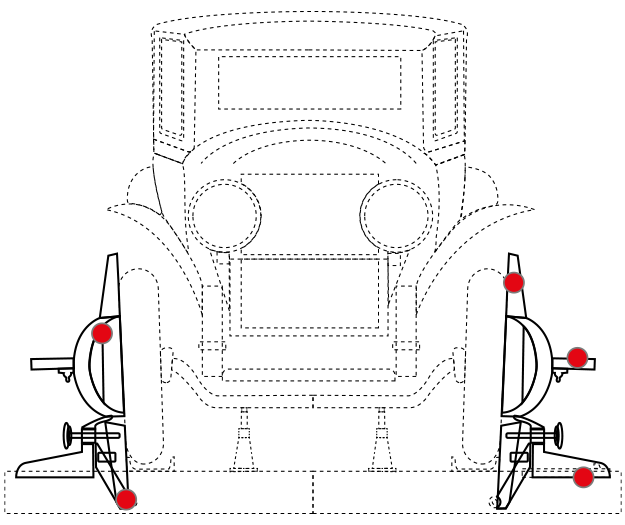

Anchor Point

Purpose: Indicates where the structure of the frame is attached to the suspension or vehicle body.

Adjustment: Fixed. Used to assess structural damage or misalignment during repair or realignment.

Cowl Mount

Purpose: Used to locate upper suspension mounting points. May also indicate shock tower or cowl panel.

Adjustment: Fixed sheet metal. May sag or move slightly due to collision damage.

Centerline

Purpose: Indicates the centerline of the wheel assembly and marks the wheel’s lateral position. This reference may vary slightly side-to-side.

Adjustment: Fixed within the suspension system. Primarily used for measurement and to verify lateral symmetry between the left and right wheels.

Anchor Point

Purpose: Same as the frame anchor point on the left side.

Adjustment: Fixed. Used as a reference for locating suspension and steering components during pushing or alignment.

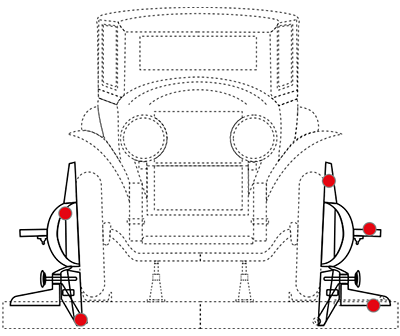

Spindle Pivot

Purpose: Represents the point at which the suspension pivots during steering.

Adjustment: Fixed location. Used to identify suspension geometry and vehicle thrust angle; may also be referenced during damage analysis.

Anchor Point

Purpose: Indicates where the structure of the frame is attached to the suspension or vehicle body.

Adjustment: Fixed. Used to assess structural damage or misalignment during repair or realignment.

Cowl Mount

Purpose: Used to locate upper suspension mounting points. May also indicate shock tower or cowl panel.

Adjustment: Fixed sheet metal. May sag or move slightly due to collision damage.

Centerline

Purpose: Indicates the centerline of the wheel assembly and marks the wheel’s lateral position. This reference may vary slightly side-to-side.

Adjustment: Fixed within the suspension system. Primarily used for measurement and to verify lateral symmetry between the left and right wheels.

Anchor Point

Purpose: Same as the frame anchor point on the left side.

Adjustment: Fixed. Used as a reference for locating suspension and steering components during pushing or alignment.

John Bean

Today!