Choosing the right alignment machine is a critical investment that impacts your shop’s efficiency, service quality, and long-term profitability. With a wide range of options available, each with different features, space requirements, and price points, it is important to think carefully about your needs before making a purchase.

This guide outlines the essential factors to consider when selecting a wheel alignment machine, from equipment type and features to ADAS compatibility and manufacturer support.

Assessing Your Shop’s Needs

The starting point for any equipment purchase is a clear understanding of your shop’s specific requirements and volume of alignment work.

Types of Vehicles Serviced

Consider the vehicles that represent the majority of your work. Wheelbase length, vehicle weight, and suspension design all play a role in determining the most suitable aligner. Ensure that the system you choose can accommodate your most common vehicle types.

Alignment Volume

High-volume shops require faster machines that reduce turnaround time and minimize downtime. Look for systems designed to handle continuous use without compromising accuracy.

Budget and Return on Investment

When budgeting, account not only for the purchase price, but also for installation, training, and ongoing maintenance. The right alignment machine should provide measurable ROI by saving labor hours, reducing errors, and limiting comebacks.

Available Floor Space

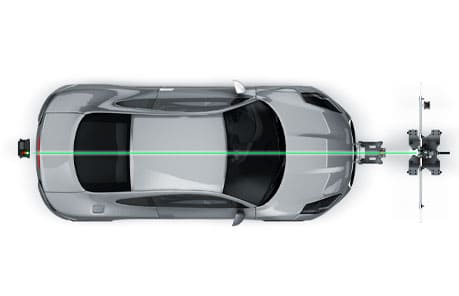

Machine size and shop layout must also be considered. If you offer ADAS calibration, these processes may require between 20’ x 30’ and 40’ x 60’ of space, depending on the manufacturer. Keep in mind that “all-in-one” systems perform alignment and calibration sequentially, not simultaneously, so workflow planning is essential.

Understanding the Types of Alignment Machines

There are several categories of alignment machines available, each suited to different shop environments.

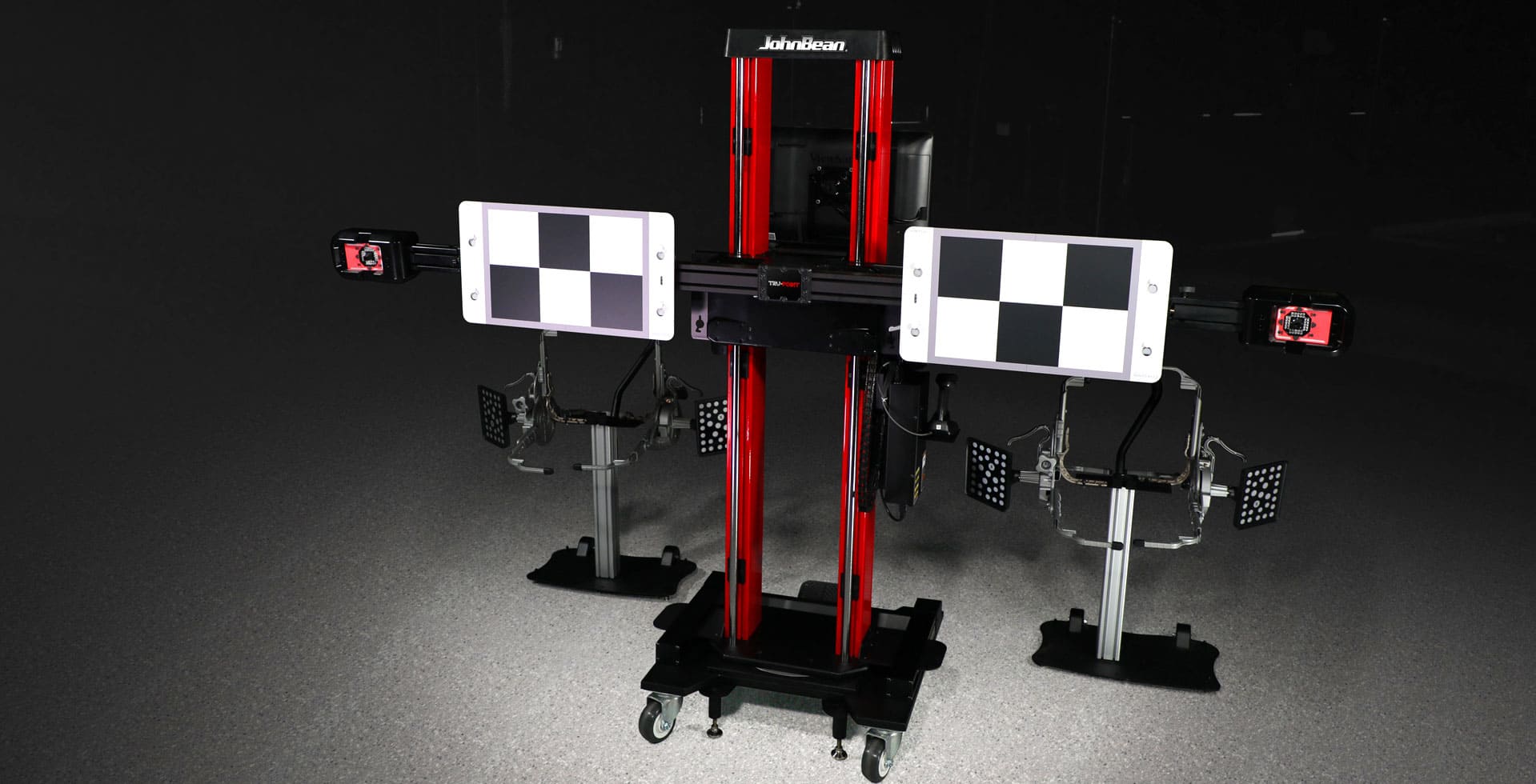

- 3D Wheel Aligners: Provide high precision and fast operation, making them ideal for shops with high throughput or specialized requirements.

- Touchless Wheel Aligners: Offer fast, no-contact operation, though they may have limitations with certain wheel finishes such as chrome or dark rims.

- Portable Aligners: Best suited for shops with limited space or for mobile operations.

Each type offers advantages and trade-offs. Selection should be based on your service mix, volume, and available space.

Key Features to Prioritize

The effectiveness of an alignment machine depends on more than just its type. Critical features to evaluate include:

- Accuracy and Repeatability: Essential for consistent camber, caster, and toe measurements.

- Speed and Workflow Efficiency: Features such as automated camera adjustments and wireless operation can save significant time.

- Durability and Reliability: Equipment should be built to withstand demanding shop conditions and frequent use.

- Software Capabilities: A robust database of vehicle specifications, regular updates, and real-time diagnostics ensure technicians can work efficiently and accurately.

- Installation and Training: Reliable manufacturers provide setup assistance and thorough training to shorten the learning curve and maximize productivity.

Manufacturer Reputation and Support

Beyond machine specifications, manufacturer reputation and long-term support are key considerations.

- Certification: Equipment certified by the Automotive Lift Institute (ALI) or meeting OEM standards provides assurance of safety and accuracy.

- Warranty and Service Plans: Comprehensive service coverage and readily available parts reduce downtime and extend the life of the equipment.

- Training and Post-Sale Support: Access to training resources ensures technicians remain proficient as new features and updates are introduced.

John Bean® equipment is trusted and approved by leading OEMs including Audi, Tesla, Hyundai, and many others. This trust reflects a century of innovation in wheel alignment technology and an ongoing commitment to precision and reliability.

Matching Capabilities with Shop Goals

The right alignment machine should align with your shop’s size, volume, and service focus. A small independent shop may prioritize compact equipment and ease of training, while larger facilities often need faster systems that can handle continuous use across multiple bays. Equipment that supports ADAS calibration, integrates with shop management systems, and provides intuitive software will position your business for long-term efficiency and growth.

It is also important to consider scalability. As vehicles become increasingly complex, your shop should be prepared to handle future service demands without requiring constant reinvestment. John Bean continues to lead in this space, from the invention of the first mechanical wheel aligner in 1925 to the latest D2 Max™ technology that simulates real-world driving conditions. This progression demonstrates not only innovation but also a commitment to providing shops with equipment that evolves alongside industry needs.

Invest with Confidence

Selecting the right alignment machine is a long-term investment in your shop’s success. Evaluate your specific needs, compare equipment types, and prioritize support and certification. Whenever possible, schedule a live demonstration to see how the system performs in a real-world environment.

With our proven history and OEM partnerships, you can make a confident decision that supports accuracy, efficiency, and readiness for the future of vehicle service.

How the Right Tire Changer Increases Shop Efficiency and Customer Throughput

How the Right Tire Changer Increases Shop Efficiency and Customer Throughput  Why Combo ADAS and Alignment Machines Hurt Shop Productivity

Why Combo ADAS and Alignment Machines Hurt Shop Productivity  Comparing Traditional vs. Computerized Wheel Alignment Systems (3D & CCD)

Comparing Traditional vs. Computerized Wheel Alignment Systems (3D & CCD)  How to Run a Successful Auto Repair Shop

How to Run a Successful Auto Repair Shop  Balancing the Details: The Role of Proper Tooling and Precise Mounting

Balancing the Details: The Role of Proper Tooling and Precise Mounting  Windshield Camera Calibration: Everything You Need to Know

Windshield Camera Calibration: Everything You Need to Know  8 Critical Factors to Consider Before Choosing Your ADAS Calibration Equipment

8 Critical Factors to Consider Before Choosing Your ADAS Calibration Equipment  What is Brake Assist?

What is Brake Assist?  The Ultimate Guide to OEM Certification

The Ultimate Guide to OEM Certification