Every vehicle rolling through your shop tells a story through its wheels. Reading that story accurately and correcting alignment issues with precision determines whether customers return satisfied or experience premature tire wear and poor handling. Your choice of alignment tools directly impacts your ability to deliver consistent precision.

What Wheel Alignment Fixes (and Why It Matters)

Wheel alignment adjusts four critical angles: camber (wheel tilt), caster (steering pivot angle), toe (wheel direction), and thrust angle (axle relationship). When these match manufacturer specifications, drivers enjoy improved fuel economy, enhanced safety, and extended tire life. Miss the mark, and customers face rapid tire wear, vehicle pulling, and compromised handling. Your alignment precision directly drives customer outcomes.

Traditional Methods: How They Work & Where They Fit

Traditional alignment uses manual measurements with strings, mechanical gauges, or laser bars. Technicians measure angles using bubble gauges, turn plates, and caster-camber gauges, focusing on either two wheels or all four.

- Advantages: Low upfront investment, full manual control, reliable on older vehicles with simpler suspensions.

- Limitations: Accuracy depends entirely on technician skill. Setup times run longer, reducing bay productivity. Different technicians produce different results on identical vehicles. Manual documentation reduces transparency with customers.

Computerized Systems: CCD & 3D Imaging

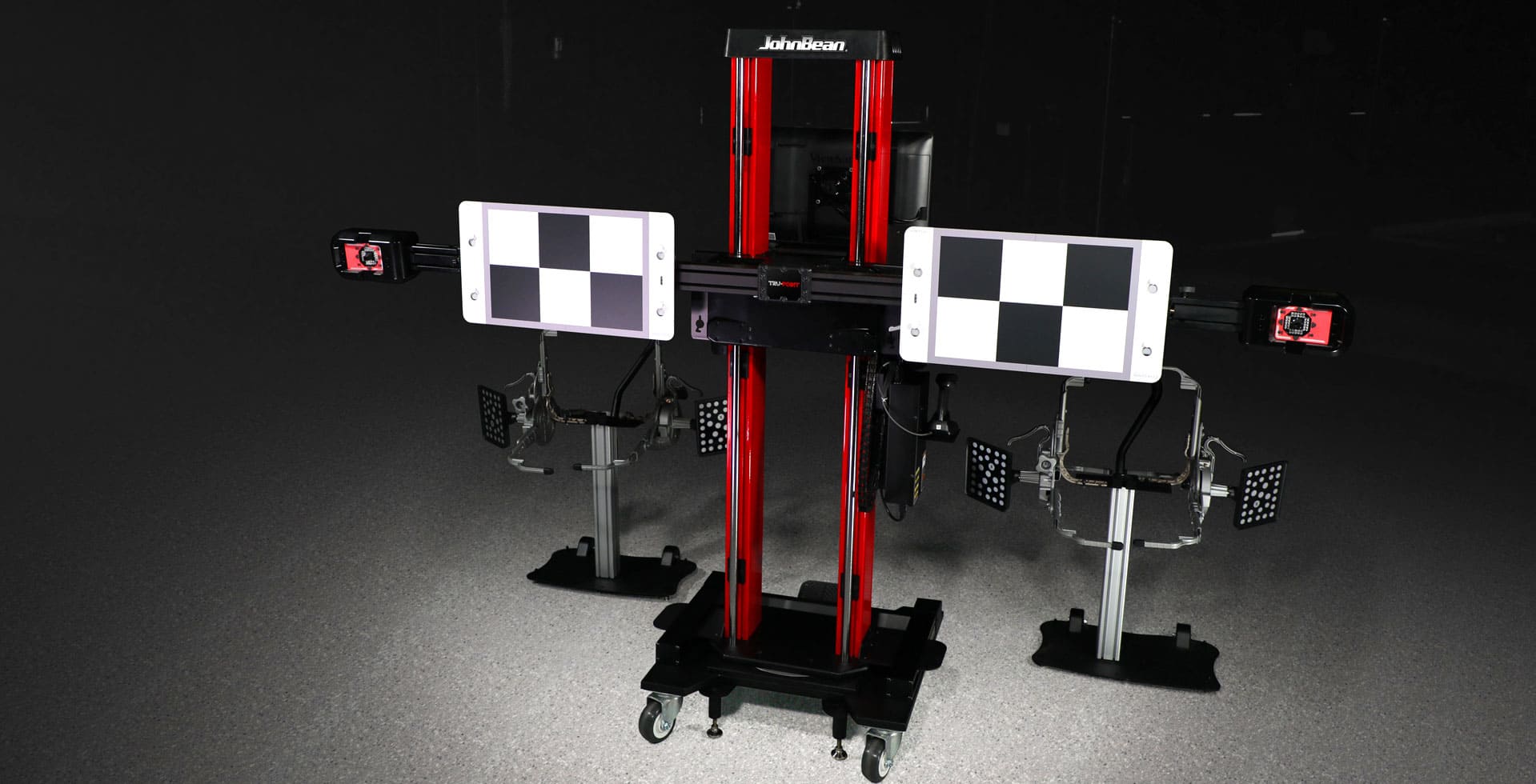

- CCD systems attach sensor heads to each wheel, communicating with a central computer that compares positions to OEM specifications, guides corrections, and verifies results automatically.

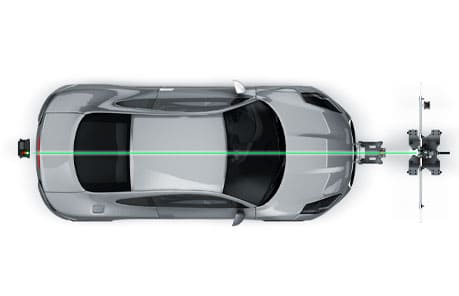

- 3D imaging systems use camera arrays tracking wheel-mounted targets to compute angles in real-time. These capture comprehensive vehicle geometry instantly, reducing setup time and eliminating human error.

Both technologies feature complete OEM databases, customer history tracking, step-by-step adjustment screens, and professional reports that demonstrate value and reduce disputes.

Accuracy & Repeatability

Traditional methods introduce variability, even skilled technicians create minor errors that compound throughout measurement. A misplaced string or unlevel gauge causes cascading inaccuracies.

3D systems deliver precision around ±0.1°, maintaining consistency regardless of operator experience. Automated sensing eliminates human variables. Repeat alignments produce virtually identical results, building confidence in your capabilities.

Speed, Workflow & Throughput

Computerized systems enable quick checks in minutes, not hours. Perform rapid inspections on the lift or shop floor to identify which vehicles need adjustments.

The John Bean V3300 combines ultra-fast cameras with error notifications that catch problems early, reducing rework and total alignment time. This allows more vehicles per day without sacrificing quality.

Space, Layout & Calibration

3D systems need clear camera-to-target sightlines but modern designs minimize space requirements. CCD systems offer greater flexibility in tight spaces. All computerized systems require periodic calibration, build this into your SOPs to maintain peak accuracy.

Technician Skill, Training & Trust

Computerized systems reduce required manual skills through on-screen guidance, shortening training time and improving team consistency. Visual displays and comprehensive reports transform customer interactions, show them exactly what’s wrong and how you fixed it, building trust and increasing service acceptance.

Economics & ROI

Higher upfront investment pays dividends through faster cycle times (more alignments daily), fewer comebacks (protecting reputation), and auditable results (preventing disputes). John Bean systems exemplify these ROI drivers through faster cameras, error prevention, and optimized workflows that translate directly to increased throughput and satisfaction.

When Traditional Still Makes Sense

Traditional methods work for budget-constrained startups, vintage vehicle specialists where original specs matter more than absolute precision, or shops performing only occasional alignments. Understanding these trade-offs helps inform decisions while acknowledging limitations in speed and repeatability.

Decision Framework: Traditional vs. CCD vs. 3D (With Examples)

- Maximum flexibility: CCD systems provide excellent results with adaptable bay requirements.

- Ultimate automation: 3D imaging delivers unmatched precision for high-volume environments.

- Tight spaces: The John Bean V2100 features rotating camera beam and tablet control with optional mobility kit.

- Maximum throughput: The John Bean V3300 combines advanced notifications, auto-tracking, audit mode, and ADAS information access for shops prioritizing efficiency.

Modern Vehicle Realities (Why “Computerized” Wins Long-Term)

Today’s vehicles demand integrated approaches. Computerized systems provide OEM procedures, TSBs, recalls, TPMS, and ADAS calibration steps within the alignment workflow, minimizing tool-switching and mistakes.

John Bean D2 Max™ technology maps real-world drive direction for improved precision, crucial as suspensions and ADAS systems grow complex. These advancements make computerized systems investments in your future.

Conclusion

The shift to computerized alignment represents a transformation in service capability and business potential. Modern vehicles and customer expectations demand the precision, speed, and professionalism only computerized systems deliver.

Explore John Bean wheel alignment machines to find your shop’s perfect solution. Whether entering professional alignment services or upgrading for growing demand, John Bean offers systems that deliver the accuracy customers deserve.

FAQs

How do computerized systems measure angles differently? Computerized systems use optical sensors or cameras capturing 3D wheel positions, calculating angles mathematically. Traditional tools rely on physical measurements with bubble levels and gauges, introducing human error.

Why do computerized aligners need calibration? Environmental factors and normal wear affect precision equipment. Calibration every 6-12 months or after relocation ensures specification-perfect results.

What space do 3D systems require? 3D systems need 12-14 feet bay length with clear camera-to-target sightlines. Modern systems like the V2180 minimize requirements through innovative design.

Which system fits my shop? Entry-level: V2180 balances capability with space efficiency. High-throughput/ADAS: V3300 combines speed, precision, and comprehensive integration.

How the Right Tire Changer Increases Shop Efficiency and Customer Throughput

How the Right Tire Changer Increases Shop Efficiency and Customer Throughput  Why Combo ADAS and Alignment Machines Hurt Shop Productivity

Why Combo ADAS and Alignment Machines Hurt Shop Productivity  How to Run a Successful Auto Repair Shop

How to Run a Successful Auto Repair Shop  How to Choose the Best Wheel Alignment Machine for Your Shop

How to Choose the Best Wheel Alignment Machine for Your Shop  Balancing the Details: The Role of Proper Tooling and Precise Mounting

Balancing the Details: The Role of Proper Tooling and Precise Mounting  Windshield Camera Calibration: Everything You Need to Know

Windshield Camera Calibration: Everything You Need to Know  8 Critical Factors to Consider Before Choosing Your ADAS Calibration Equipment

8 Critical Factors to Consider Before Choosing Your ADAS Calibration Equipment  What is Brake Assist?

What is Brake Assist?  The Ultimate Guide to OEM Certification

The Ultimate Guide to OEM Certification