Advanced Driver Assistance Systems (ADAS) have transformed from luxury features into standard safety equipment across virtually every new vehicle rolling off production lines today. These sophisticated systems, including automatic emergency braking, lane departure warning, adaptive cruise control, and blind spot monitoring, rely on precise calibration to function correctly and keep drivers safe.

For auto body shops, this technological step forward presents both tremendous opportunity and significant responsibility. Properly calibrated ADAS systems can be the difference between a successful repair and a catastrophic liability issue. When these systems aren’t calibrated correctly after repairs, windshield replacements, or suspension work, they may fail to protect drivers when needed most.

The revenue potential from offering in-house ADAS calibration services is substantial, but choosing the wrong equipment can turn this opportunity into a costly mistake. The investment in calibration equipment is important, and the decision you make today will impact your shop’s capabilities and profitability for years to come.

This guide will walk you through eight critical factors that should drive your purchasing decision, helping you avoid expensive missteps while positioning your shop for future growth in an increasingly ADAS-dependent automotive landscape.

1. Vehicle Compatibility

Your calibration equipment’s vehicle coverage determines which customers you can serve and which revenue opportunities you’ll capture. The automotive market includes dozens of manufacturers, each with unique calibration requirements and procedures.

Your ADAS equipment should be compatible with both domestic and import manufacturers, from Toyota, Nissan, Hyundai, Mercedes-Benz, and emerging electric vehicle brands like Tesla. However, coverage isn’t just about the manufacturer, you need equipment that handles both current model years and older vehicles that will continue requiring service for years to come.

Consider your local market carefully. If you primarily service domestic vehicles, extensive European coverage might be unnecessary initially. Conversely, shops in areas with high import vehicle concentrations need robust coverage across Asian and European manufacturers.

Look for an ADAS calibration system that regularly updates their vehicle coverage database and clearly communicates their expansion roadmap. The automotive landscape changes rapidly, and your equipment should evolve with it.

2. Calibration Accuracy

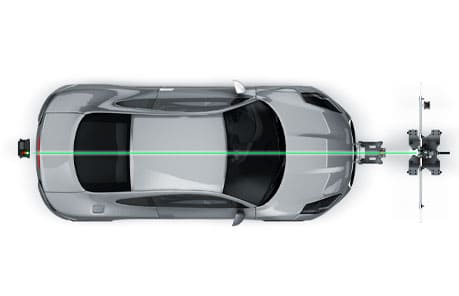

Precision isn’t negotiable when it comes to ADAS calibration. These systems operate within extremely tight tolerances—often measuring in fractions of degrees or millimeters. Even minor calibration errors can cause lane keeping systems to pull vehicles off course or prevent automatic emergency braking from activating in time.

Quality calibration equipment provides multiple verification methods to ensure accuracy. Look for systems that offer real-time feedback during the calibration process, allowing technicians to make adjustments before completing the procedure. Built-in quality control features should verify that calibrations meet OEM specifications before you finish the job.

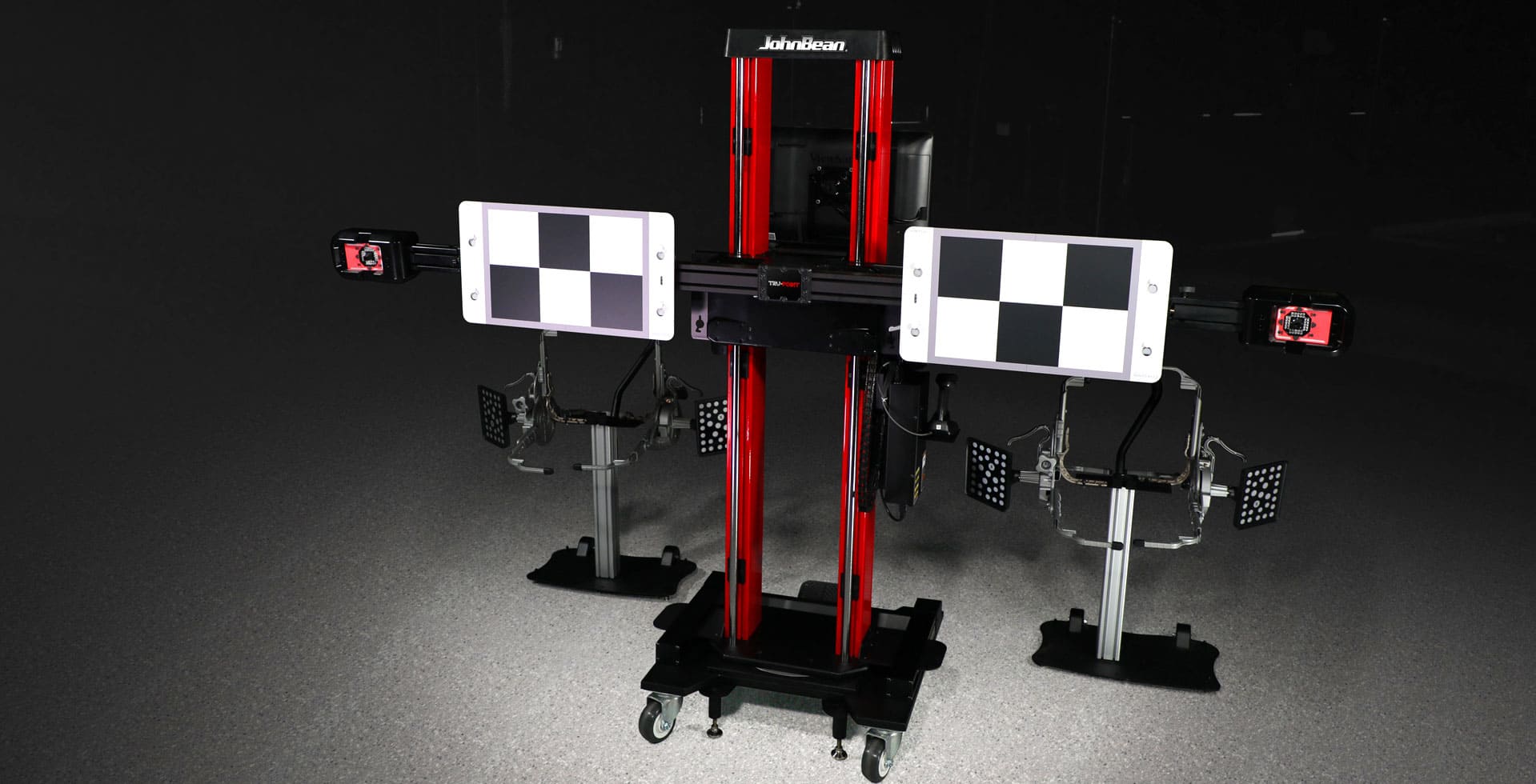

The most reliable systems incorporate 3D measurement capabilities (like our Tru-Point system) and precision alignment tools that eliminate guesswork. These features help ensure that every calibration meets strict OEM standards, protecting both your customers and your shop from liability issues.

3. Cost Considerations

ADAS calibration equipment represents a significant capital investment, often costing thousands for comprehensive systems. However, we find it more valuable to look beyond the initial purchase price to understand your total investment and projected returns.

Calculate your expected return on investment based on local market rates for calibration services, which typically range from $150 to $400 per procedure. Factor in your projected monthly calibration volume and consider how quickly the equipment will pay for itself.

Don’t forget ongoing costs including software subscription fees, database updates, and maintenance contracts. Some providers charge substantial annual fees for keeping your system current with new vehicle models and calibration procedures. These recurring costs can significantly impact your long-term profitability.

Consider financing options that align with your cash flow needs. Many equipment providers offer leasing programs that reduce upfront costs while including maintenance and update services.

4. Training and Support

Even the most sophisticated calibration equipment is only as effective as the technicians operating it. ADAS calibration requires specialized knowledge about individual vehicle systems, proper procedures, and safety protocols.

Comprehensive training should cover both equipment operation and broader ADAS theory, helping your technicians understand not just how to use the tools, but why specific procedures are necessary. Look for providers offering certification programs that enhance your shop’s credibility with customers and insurance companies.

Technical support availability is equally important. When calibration equipment malfunctions, downtime directly impacts revenue. Prioritize providers offering responsive technical support with knowledgeable staff who understand both the equipment and automotive applications.

Some manufacturers provide ongoing education resources, including webinars, technical bulletins, and updated training materials as technology evolves. These resources help ensure your team stays current with emerging calibration requirements.

5. Space Requirements

ADAS calibration equipment demands significant shop space, and smaller facilities can limit your equipment options. Most systems require dedicated bay space with specific minimum dimensions, ceiling heights, and environmental controls.

Static calibration procedures typically need 20-30 feet of clear space in front of the vehicle, while dynamic calibrations may require access to open road areas. Ceiling height requirements vary but often exceed standard shop specifications to accommodate tall calibration targets and equipment.

Lighting conditions significantly impact calibration accuracy. Many systems require controlled lighting environments or specific illumination levels. Consider whether your facilities meet these requirements or if you’ll need to invest in lighting modifications.

Environmental factors like temperature stability and vibration isolation can affect calibration precision. Evaluate your shop’s conditions and determine if additional climate control or vibration dampening measures are necessary.

6. System Integration

Modern auto body shops rely on integrated workflows to stay efficient and profitable. Your ADAS calibration equipment should complement existing tools and shop management systems rather than adding complexity.

Look for equipment that interfaces with your current diagnostic scanners and estimation systems. A focus on integration allows technicians to access procedures directly from diagnostic trouble codes and automatically update their repair documentation.

Connectivity with shop management software helps track calibration services, manage scheduling, and generate customer reports. Some systems offer cloud-based data storage that enables features like remote monitoring and automated reporting.

Consider how the equipment fits into your overall workflow. Equipment that requires new and complicated processes or specialized technicians may create bottlenecks that make work more difficult instead of repeatable.

7. Compliance and Certification

OEM approval and certification provide important credibility and may be required by some insurance companies or fleet customers. Equipment recognized by major manufacturers demonstrates that your shop meets strict accuracy and reliability standards.

Insurance company recognition is increasingly important as insurers learn more about ADAS repair requirements. Using certified equipment helps protect your shop from liability claims and may be required for warranty coverage on calibration services.

Stay informed about evolving regulations and requirements. Some jurisdictions are developing specific standards for ADAS calibration equipment and procedures. Choosing equipment that exceeds current requirements provides protection against future regulatory changes.

Documentation capabilities are essential for compliance. Your equipment should generate detailed calibration reports that satisfy insurance requirements and provide clear evidence of proper procedures.

8. Future-Proofing

The automotive industry continues evolving rapidly, with new ADAS features appearing regularly and existing systems becoming more sophisticated. Your equipment investment should work with this evolution without requiring complete replacement every few years.

Consider emerging technologies like autonomous vehicle systems, advanced radar configurations, and new sensor types. While these new technologies may seem distant, they’re closer than many realize, and early preparation sets you up for success down the road.

Scalability matters as your volume of work grows. Equipment that handles increasing workloads without the need for more space or staff offers better long-term profitability.

Software update policies significantly impact future capabilities. Providers that regularly release updates with new vehicle coverage and enhanced features help ensure you see more returns on your initial investment.

Conclusion

Choosing ADAS calibration equipment requires careful evaluation of multiple factors that will impact your shop’s capabilities and profitability for years to come. Vehicle compatibility, calibration accuracy, and cost considerations form the foundation of your decision, while training, space requirements, and system integration determine how effectively you can use the technology.

Compliance requirements and future-proofing considerations ensure your investment provides long-term value. Don’t rush this important decision—thorough research and careful planning will help you choose equipment that positions your shop for success.

Ready to explore your options? Discover our comprehensive ADAS calibration solutions designed to meet the needs of modern auto body shops. For additional insights into ADAS technology and calibration best practices, check out our complete ADAS calibration guide and learn more about steering angle sensor calibration requirements.

How the Right Tire Changer Increases Shop Efficiency and Customer Throughput

How the Right Tire Changer Increases Shop Efficiency and Customer Throughput  Why Combo ADAS and Alignment Machines Hurt Shop Productivity

Why Combo ADAS and Alignment Machines Hurt Shop Productivity  Comparing Traditional vs. Computerized Wheel Alignment Systems (3D & CCD)

Comparing Traditional vs. Computerized Wheel Alignment Systems (3D & CCD)  How to Run a Successful Auto Repair Shop

How to Run a Successful Auto Repair Shop  How to Choose the Best Wheel Alignment Machine for Your Shop

How to Choose the Best Wheel Alignment Machine for Your Shop  Balancing the Details: The Role of Proper Tooling and Precise Mounting

Balancing the Details: The Role of Proper Tooling and Precise Mounting  Windshield Camera Calibration: Everything You Need to Know

Windshield Camera Calibration: Everything You Need to Know  What is Brake Assist?

What is Brake Assist?  The Ultimate Guide to OEM Certification

The Ultimate Guide to OEM Certification