Running a successful auto repair business requires more than technical skill. It demands planning, efficiency, and a commitment to quality that keeps customers returning. While any shop can perform basic services, the most profitable operations distinguish themselves through reliable processes, advanced equipment, and a focus on long-term growth.

At John Bean®, we have worked with shops of every size, from independent garages to OEM-certified centers. Over decades of experience, we’ve seen that the most consistent performers share several core elements that define their operations and position them for success.

Strategic Planning: A Clear Foundation for Growth

Every profitable shop begins with a structured plan. This includes financial forecasts, measurable milestones, and a defined roadmap for both short and long-term goals.

A well-established brand is also critical. A consistent logo, tone, and visual identity build trust with customers and help differentiate your business in a competitive market. Shops that overlook this step often struggle to establish credibility, while those that invest in branding become recognized, reliable service providers within their communities.

Marketing and Customer Acquisition: Visibility That Drives Business

Bringing customers through the door requires more than word of mouth. A modern shop must prioritize digital visibility. Maintaining a current Google Business Profile, investing in local SEO, and sending service reminders through email or SMS all help keep your business top-of-mind.

Convenience is equally important. Customers increasingly expect online booking, real-time service tracking, and transparent communication. By offering these features, shops reduce friction, improve the customer experience, and strengthen repeat business.

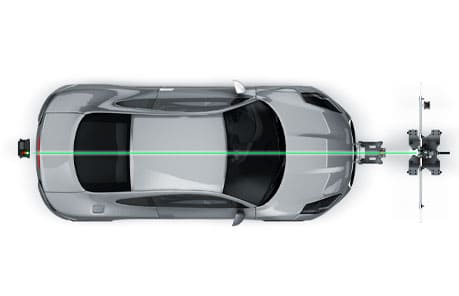

Expanding service offerings also supports growth. For example, integrating ADAS calibration with wheel service ensures modern vehicles receive complete care while generating new revenue opportunities.

Efficiency and Workflow: Organizing for Accuracy and Speed

Shops that consistently meet customer expectations prioritize efficiency in their workflow. Dedicated service zones, such as alignment bays, tire service areas, and customer waiting rooms, help streamline daily operations.

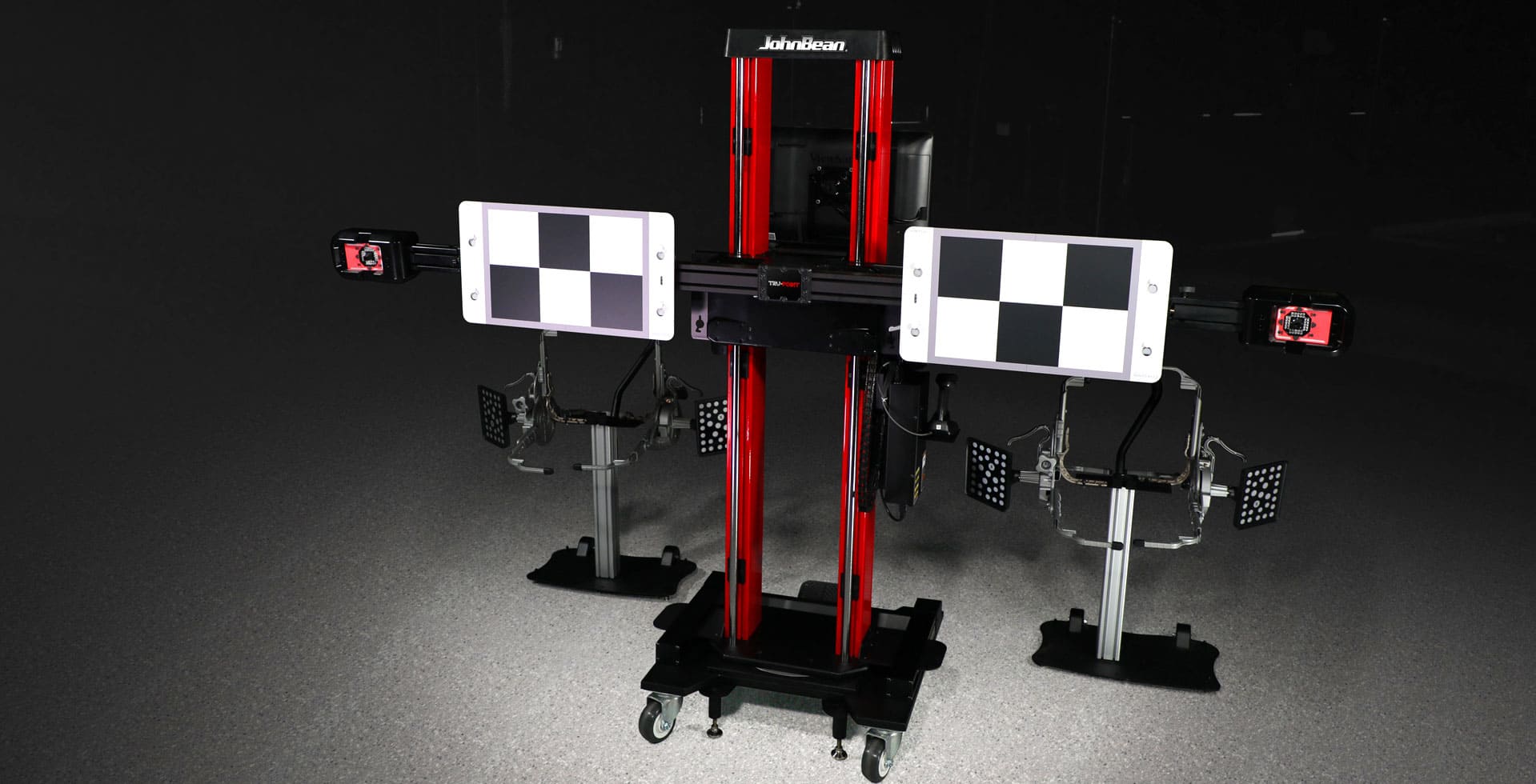

Technology further enhances efficiency. Automated shop management systems, digital diagnostics, and connected equipment allow technicians to work faster with fewer errors. Our V3300 system, for instance, provides guided processes and real-time feedback, reducing setup time and improving accuracy.

Offering additional services during existing repair work, such as performing ADAS calibration after windshield replacement, also improves efficiency while delivering comprehensive solutions for customers.

Investing in Equipment: Reliability That Pays Back

The quality of equipment directly influences a shop’s reputation. Machines that fail or produce inconsistent results undermine customer trust and create costly delays. In contrast, high-quality equipment supports long-term profitability by delivering accuracy and minimizing downtime.

When evaluating equipment, consider:

- Capacity – Can the system meet your daily workload?

- Space utilization – Does it fit your shop layout without limiting throughput?

- Future readiness – Is it certified for ADAS, compatible with OEM standards, and supported by training?

We are an OEM-approved partner for leading manufacturers including Audi, Tesla, Hyundai, and Kia. This recognition ensures our systems meet the strictest requirements for safety and performance, helping shops deliver results that match manufacturer specifications.

Skilled Teams and Ongoing Training: People Behind the Process

A shop’s workforce is its greatest asset. Hiring technicians who align with the business’s culture and service expectations creates a strong foundation. But sustained success requires continuous development.

Industry certifications such as ASE or I-CAR demonstrate capability, while ongoing training ensures technicians are prepared for new technologies. We support this through equipment with guided software and through access to training resources that help staff adapt to emerging challenges like ADAS calibration.

Employee satisfaction also matters. Fair compensation, professional development, and recognition programs foster loyalty, reduce turnover, and create a better overall customer experience.

Supplier and Inventory Management: Building Reliability Into Operations

Reliable supplier relationships are essential to maintaining consistent operations. Partnerships with dependable vendors help stabilize costs and ensure timely deliveries. Inventory management systems further reduce delays by preventing shortages and avoiding overstock.

We apply the same principle in its partnerships. Through Snap-on® Total Shop Solutions, we connect shops with a family of trusted brands that provide comprehensive repair solutions, from alignment systems to diagnostics and lifts. This ecosystem enables shops to work with confidence, knowing every part of their operation is supported.

Customer Experience: Service Beyond the Repair

Customers judge their experience not only on the quality of the repair but also on how they were treated. Clear communication about pricing, timelines, and scope of work builds trust before the repair begins.

Amenities such as clean waiting areas, Wi-Fi access, or loaner vehicles demonstrate professionalism. Post-service engagement, including review requests and quick responses to feedback, extends the customer relationship beyond the transaction.

For advanced services, validation matters. Our Tru-Point™ calibration system provides compliance reports that document work quality, giving customers peace of mind and protecting shops from liability.

Continuous Improvement and Technical Awareness: Staying Ahead

The automotive industry is rapidly evolving. Shops that prioritize continuous improvement, through regular quality checks, adherence to safety protocols, and awareness of new technologies remain competitive.

Emerging demands such as EV servicing and advanced ADAS calibration require equipment and processes that can adapt. Incorporating OEM-approved technology and connected systems, such as our D2 Max™, ensures shops are prepared for future requirements.

Building a Profitable Shop

A successful repair shop is not built overnight. It grows through careful planning, effective marketing, efficient workflow, reliable equipment, skilled people, and a commitment to delivering exceptional customer experiences.

For nearly a century, John Bean has provided equipment and support that enable shops to achieve these goals. By investing in precision, innovation, and training, your business can deliver consistent results today while preparing for the challenges of tomorrow.

Explore our complete range of equipment and Total Shop Solutions to learn how the right partner can help you strengthen your shop’s performance and profitability.

How the Right Tire Changer Increases Shop Efficiency and Customer Throughput

How the Right Tire Changer Increases Shop Efficiency and Customer Throughput  Why Combo ADAS and Alignment Machines Hurt Shop Productivity

Why Combo ADAS and Alignment Machines Hurt Shop Productivity  Comparing Traditional vs. Computerized Wheel Alignment Systems (3D & CCD)

Comparing Traditional vs. Computerized Wheel Alignment Systems (3D & CCD)  How to Choose the Best Wheel Alignment Machine for Your Shop

How to Choose the Best Wheel Alignment Machine for Your Shop  Balancing the Details: The Role of Proper Tooling and Precise Mounting

Balancing the Details: The Role of Proper Tooling and Precise Mounting  Windshield Camera Calibration: Everything You Need to Know

Windshield Camera Calibration: Everything You Need to Know  8 Critical Factors to Consider Before Choosing Your ADAS Calibration Equipment

8 Critical Factors to Consider Before Choosing Your ADAS Calibration Equipment  What is Brake Assist?

What is Brake Assist?  The Ultimate Guide to OEM Certification

The Ultimate Guide to OEM Certification