Picture a busy Monday morning: three alignment jobs scheduled, two vehicles needing ADAS calibration after windshield replacements. With a combination ADAS and alignment machine, all five customers wait for the same bay. This scenario plays out daily in shops nationwide, creating workflow bottlenecks that directly impact your bottom line.

While manufacturers market integrated systems as space-saving solutions, the reality proves different. Combination machines create workflow bottlenecks by forcing two processes into a single bay, restrict valuable shop space, and complicate technician training. The integrated setup often creates more operational challenges than it solves.

Scheduling Conflicts and Workflow Bottlenecks

A combination machine monopolizes a single bay for two separate tasks, creating a productivity chokepoint. When a technician performs a wheel alignment, vehicles needing ADAS calibration sit idle. The machine handles one job at a time, eliminating multitasking and forcing scheduling delays as vehicles queue up. Service advisors must turn away customers or push calibrations to tomorrow, frustrating those who expect prompt service.

The problem gets worse when vehicles require both services sequentially. A single vehicle occupies your lift for extended periods, blocking other profitable alignment jobs. Where you might complete three or four alignments in the time required for one ADAS calibration, the combined system reduces total job volume and directly impacts daily revenue.

Demanding and Inflexible Bay Requirements

ADAS calibration demands specific environmental conditions that transform your alignment bay into a specialized workspace:

- Perfectly level floors

- Controlled lighting

- Clutter-free areas

These requirements essentially disqualify the bay from standard mechanical work. Unlike standalone equipment that technicians can move as needed, combination machines anchor themselves to one location, forcing other profitable jobs like suspension repairs or brake work to wait or relocate.

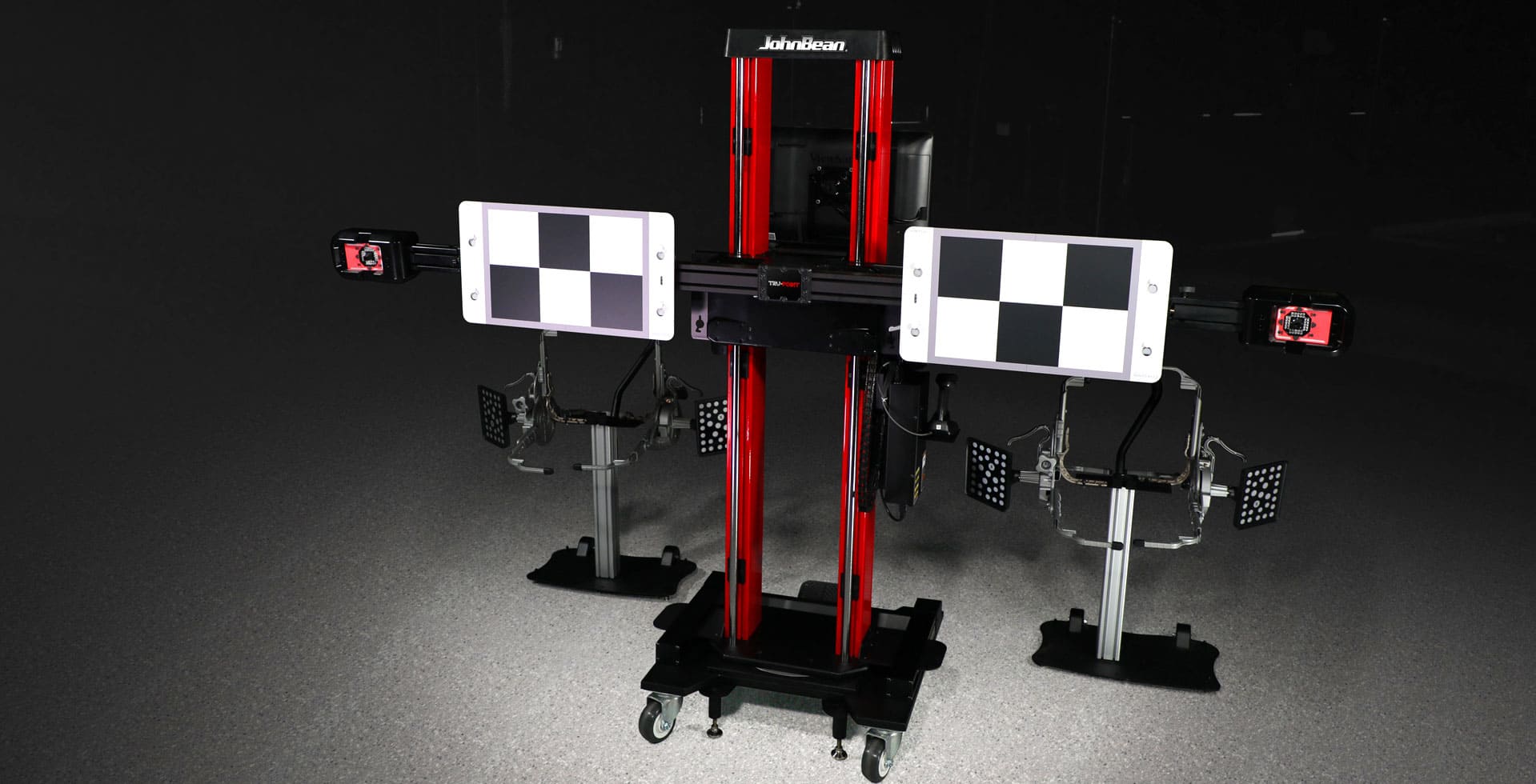

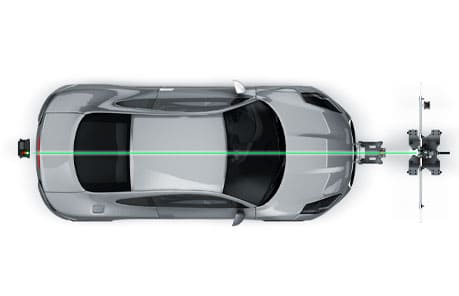

Shop efficiency suffers when bays become locked into lengthy calibration setups that prevent flexible workflow. Innovative systems like Tru-Point eliminate many rigid requirements through advanced floor compensation capabilities, allowing accurate calibration on surfaces with up to 4 degrees of variation, flexibility that combination machines cannot match.

Specialized Expertise and Training Challenges

Combination machines require advanced knowledge that exceeds what either system demands individually. Each manufacturer implements unique ADAS calibration procedures with specific prompts for each make and model. Technicians must master these variations while maintaining alignment proficiency, creating more opportunities for error compared to dedicated single-purpose equipment.

The training burden extends beyond initial certification, integrated systems demand extensive programs combining two distinct skill sets, plus continuous learning to stay current with evolving technology. This creates practical staffing challenges: when your alignment technician calls in sick, can your ADAS specialist operate the combination machine effectively? Cross-training requirements don’t exist with dedicated systems where specialists focus on their core competencies.

Higher Risk of Costly Mistakes

ADAS sensors rely on millimeter-level precision where minor errors, invisible to the human eye, compromise sensor accuracy. These mistakes lead to critical safety feature failures in lane departure warning, adaptive cruise control, and automatic emergency braking, putting customers at risk and your shop at liability. Combination machines complicate troubleshooting when problems arise, forcing technicians to diagnose issues across two interconnected processes.

Is the problem in the alignment? The calibration targets? The machine’s setup? Complex troubleshooting consumes valuable technician hours while the bay remains unusable. Rework compounds these problems exponentially, every minute spent correcting mistakes means another customer waits and your reputation takes another hit. The interconnected nature of combination machines makes isolating problems more time-consuming than dedicated systems where issues remain contained to one process.

Limited Scalability and Growth

A single 2-in-1 machine restricts business expansion when ADAS calibration demand accelerates. ADAS calibrations take significantly longer than alignments, in the time required for one calibration, your shop could complete multiple profitable alignments. This time disparity creates a service volume ceiling that becomes increasingly problematic as your business grows.

Shops with standalone alignment racks and portable ADAS calibration systems maximize bay usage through parallel processing. Multiple technicians work on different vehicles simultaneously, maintaining steady workflow during peak periods. This flexibility translates directly to profitability, separate equipment models consistently deliver higher productivity and revenue than restrictive 2-in-1 setups. Adding a second combination machine requires the same significant investment, while shops can add portable ADAS capability incrementally, spreading costs while immediately increasing capacity.

Making the Smart Investment for Your Shop’s Future

The promise of combination machines, saving space while offering convenience, rarely materializes in real-world operations. Instead, these systems create bottlenecks that limit productivity, restrict flexibility, and cap revenue potential. Leading shops recognize that dedicated systems deliver superior results.

By investing in separate, purpose-built ADAS calibration systems and wheel alignment machines you gain:

- Flexibility to adapt to changing demands while maximizing bay utilization

- Technicians who specialize in their expertise areas

- Service advisors who schedule more efficiently

- Customers who receive faster, more reliable service

Choose systems that grow with your business, not ones that constrain it.

How the Right Tire Changer Increases Shop Efficiency and Customer Throughput

How the Right Tire Changer Increases Shop Efficiency and Customer Throughput  Comparing Traditional vs. Computerized Wheel Alignment Systems (3D & CCD)

Comparing Traditional vs. Computerized Wheel Alignment Systems (3D & CCD)  How to Run a Successful Auto Repair Shop

How to Run a Successful Auto Repair Shop  How to Choose the Best Wheel Alignment Machine for Your Shop

How to Choose the Best Wheel Alignment Machine for Your Shop  Balancing the Details: The Role of Proper Tooling and Precise Mounting

Balancing the Details: The Role of Proper Tooling and Precise Mounting  Windshield Camera Calibration: Everything You Need to Know

Windshield Camera Calibration: Everything You Need to Know  8 Critical Factors to Consider Before Choosing Your ADAS Calibration Equipment

8 Critical Factors to Consider Before Choosing Your ADAS Calibration Equipment  What is Brake Assist?

What is Brake Assist?  The Ultimate Guide to OEM Certification

The Ultimate Guide to OEM Certification