Modern vehicles are equipped with sophisticated cameras that watch the road ahead, helping you stay safe through features like lane departure warnings and automatic emergency braking. But here’s something many drivers don’t realize: these cameras need precise positioning to work correctly, and that’s where windshield camera calibration becomes essential.

In this guide, we’ll walk you through everything you need to know about windshield camera calibration from what it is to why it’s crucial for your vehicle’s safety systems. As experts in ADAS calibration technology, we’ll show you how proper calibration keeps your advanced driver assistance system functioning as intended and protecting you on every drive.

What Is Windshield Camera Calibration?

Windshield camera calibration is the precise process of aligning the cameras embedded in your windshield to ensure they accurately perceive the road environment. These ADAS cameras need exact positioning to function correctly, as even a slight misalignment can cause your safety features to malfunction or provide false warnings.

The calibration process essentially “teaches” your vehicle’s camera where it should be looking and how to interpret what it sees. Think of it as setting up a security camera in your home, you need to position it correctly to monitor the right area effectively. Your windshield camera works similarly, requiring precise calibration to maintain vehicle safety and performance.

When Windshield Camera Calibration Is Needed

Several scenarios require windshield camera recalibration to ensure your advanced safety system continues working properly:

Windshield replacement is the most common trigger for calibration. When technicians install a new windshield, the camera’s position may shift slightly, affecting its field of view and accuracy.

Vehicle accidents can knock cameras out of alignment, even if the windshield itself isn’t damaged. Any collision affecting the front of your vehicle potentially impacts camera positioning.

Sensor replacements or repairs require recalibration to ensure the new or repaired components integrate properly with existing safety systems.

Many vehicle manufacturers recommend regular calibration checks, and some regions have legal requirements for proper calibration following certain repairs. Insurance companies increasingly recognize calibration as a necessary part of comprehensive vehicle repair, often covering these services when associated with windshield work.

How Windshield Camera Calibration Works

The calibration process involves two main approaches, each designed for specific situations and vehicle requirements.

Static Calibration

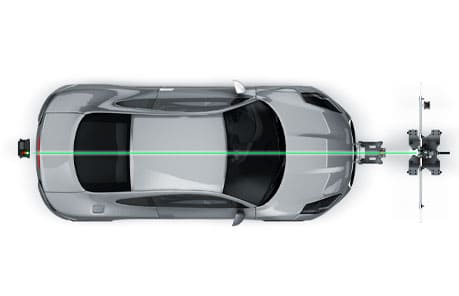

Static calibration uses specialized targets and equipment in a controlled environment, typically an auto service bay. During this process, technicians position precise targets at specific distances and angles relative to your vehicle, allowing the camera to “learn” reference points for proper operation.

This method requires exact measurements and positioning, as the camera needs to recognize these targets according to manufacturer specifications. The controlled environment eliminates variables like lighting changes or moving objects that could interfere with the calibration process.

Dynamic Calibration

Dynamic calibration requires driving the vehicle under specific conditions to recalibrate the system while in motion. This method allows the camera to adjust to real world driving scenarios, recognizing lane markings, other vehicles, and road conditions during the calibration process.

Some vehicles require dynamic recalibration after static calibration, while others use dynamic calibration as the primary method. The process typically involves driving on well marked roads at specific speeds and following particular routes outlined by the vehicle manufacturer.

The Role of Professional Calibration Equipment

Specialized equipment ensures accuracy in windshield camera recalibration, making the difference between a successful calibration and potential safety risks down the road.

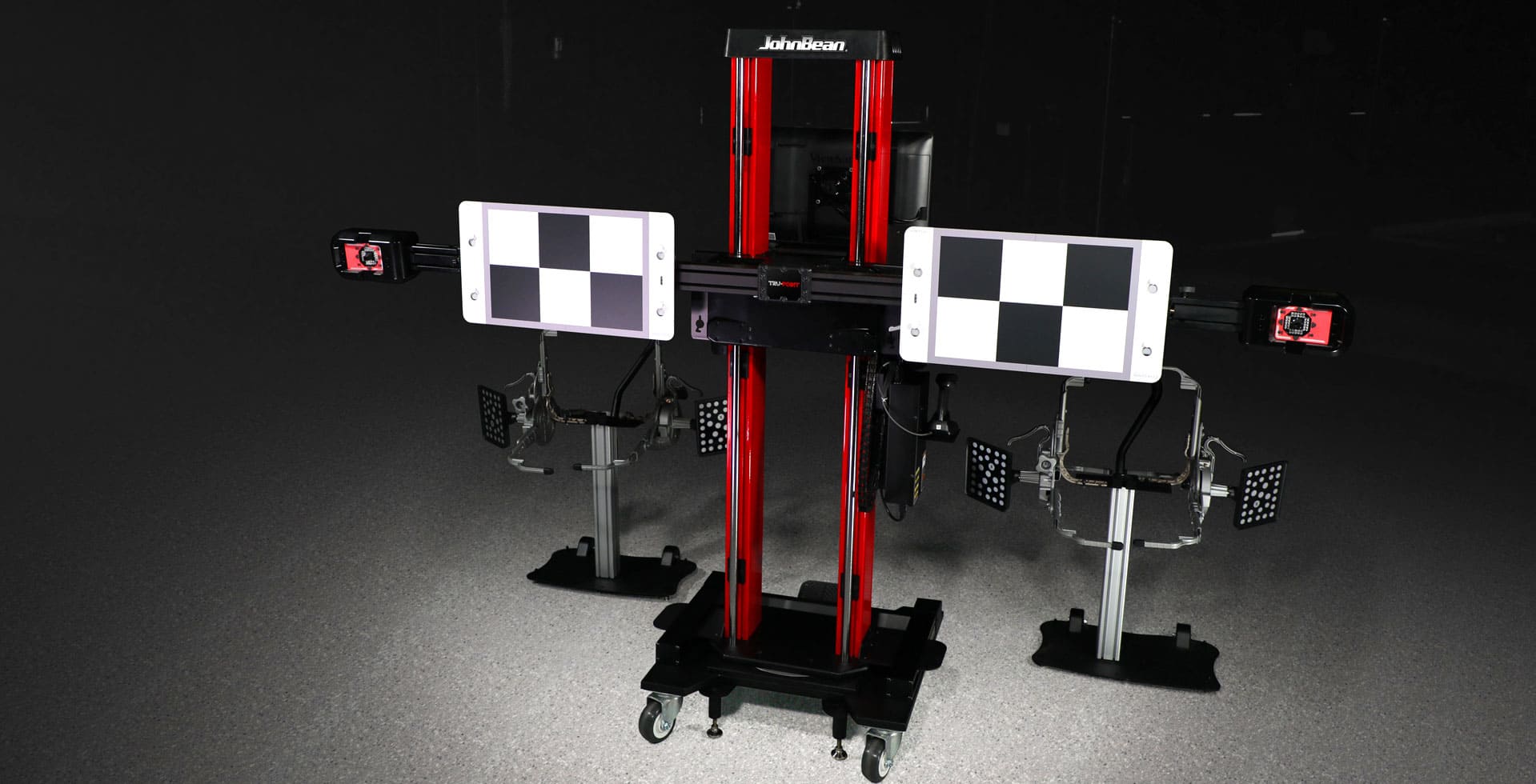

Professional ADAS calibration systems like our Tru-Point system use a simplified user interface and follow OEM service information for proper placement the first time. The calibration process follows four critical steps:

Check involves ensuring the vehicle is in proper wheel alignment and assessing floor level conditions at the vehicle, while validating the Tru-Point position relative to both the vehicle and floor slope.

Place utilizes all collected data from the checking phase, ensuring the target is positioned in the preferred OEM location with respect to shop environmental conditions.

Calibrate allows technicians to proceed confidently, knowing that calibration will succeed as long as the vehicle was repaired properly.

Prove provides comprehensive reports and 3D imaging validation of target placement, ensuring proper proof of placement and calibration for OEM standards.

The 3D imaging technology found in Tru-Point eliminates the need for lasers, tape measures, strings, plumb bobs, or drawing on the floor, saving time and training for technicians attempting new calibrations.

Following Manufacturer Specifications

ADAS sensors only know to look for targets as defined by the OEM they don’t know when they’re installed or repaired incorrectly. This creates the possibility of false successful calibrations in various scenarios:

- Improper repair of the sensor mount location

- Inappropriate troubleshooting of failed calibrations, then moving targets around until the system passes

- Resizing or repositioning targets to save shop space

- Using non OEM grade targets for calibrations

Tru-Point meets or exceeds OEM expectations for accuracy, repeatability, and target quality. With six OEM approvals and growing, the system ensures proper calibration methods through strong manufacturer relationships.

This approach means that failed calibrations are almost exclusively tied to improper sensor repair, mounting, or replacement; as well as environmental conditions, rather than calibration equipment issues. Following OEM specifications also reduces shop liability should the vehicle be involved in an accident down the road.

Why Windshield Camera Calibration Is Important

Connection Between Calibration and ADAS Functionality

Proper calibration ensures your vehicle’s safety features work exactly as designed. When cameras are correctly aligned, systems like lane departure warnings can accurately detect when you’re drifting out of your lane. Other systems like adaptive cruise control use sensor fusion to process data from both cameras and sensors to maintain proper distance from vehicles ahead.

Misalignment can cause false warnings that train drivers to ignore legitimate alerts, or worse, prevent safety features from activating when needed. For example, an improperly calibrated camera might not detect an obstacle in time for automatic emergency braking to engage effectively.

Modern vehicles rely on precise calibration for features like:

- Lane keeping assist systems

- Forward collision warnings

- Pedestrian detection

- Traffic sign recognition

- Adaptive cruise control

Risks of Skipping Calibration

Avoiding windshield calibration creates serious safety risks that extend beyond malfunctioning ADAS features. Reduced system reliability can lead to driver overconfidence in safety features that aren’t working properly, potentially increasing collision risk.

Skipping calibration may void vehicle warranties or create legal liabilities if safety systems fail to perform as expected. Insurance companies are becoming more aware of calibration requirements, and some may deny claims if proper calibration wasn’t performed following repairs.

The consequences of improper or missing calibration can include:

- Malfunctioning lane departure warnings

- Ineffective automatic emergency braking

- False alerts that desensitize drivers to real warnings

- Complete failure of advanced safety systems

Windshield Camera Calibration Costs and Insurance

Typical Cost Range for Calibration Services

Calibration costs vary depending on several factors, including your vehicle model, manufacturer requirements, and local labor costs. Some vehicles require both static and dynamic calibration, which increases the total cost but ensures comprehensive system accuracy. Luxury vehicles or those with multiple camera systems may require more complex calibration procedures, affecting pricing.

Factors influencing calibration costs include:

- Vehicle make and model complexity

- Number of cameras requiring calibration

- Type of calibration required (static, dynamic, or both)

- Regional labor rates

- Availability of specialized equipment

Insurance Coverage for Calibration

Many insurance providers now cover calibration costs when associated with windshield replacement or accident repairs. This coverage reflects the industry’s recognition that calibration is an essential part of proper vehicle repair, not an optional service.

Before scheduling calibration services, check with your insurance provider to confirm coverage details. Some policies automatically include calibration with glass replacement, while others may require specific authorization.

When working with insurance companies, ensure your service provider can document the calibration process and provide proof that work was completed according to manufacturer specifications. This documentation protects both you and the repair facility should questions arise later.

Conclusion

Windshield camera calibration isn’t just a technical requirement, it’s a critical safety measure that ensures your vehicle’s advanced driver assistance systems work as intended. From preventing false warnings to ensuring automatic emergency braking functions properly, calibration keeps you protected on every drive.

Whether you’re dealing with windshield replacement, accident repairs, or routine maintenance, never skip the calibration process. The investment in proper calibration pays dividends in safety, reliability, and peace of mind.

Ready to learn more about ADAS calibration? Explore our comprehensive ADAS calibration guide or discover our industry leading ADAS calibration systems that ensure precise, OEM compliant calibration every time.

How the Right Tire Changer Increases Shop Efficiency and Customer Throughput

How the Right Tire Changer Increases Shop Efficiency and Customer Throughput  Why Combo ADAS and Alignment Machines Hurt Shop Productivity

Why Combo ADAS and Alignment Machines Hurt Shop Productivity  Comparing Traditional vs. Computerized Wheel Alignment Systems (3D & CCD)

Comparing Traditional vs. Computerized Wheel Alignment Systems (3D & CCD)  How to Run a Successful Auto Repair Shop

How to Run a Successful Auto Repair Shop  How to Choose the Best Wheel Alignment Machine for Your Shop

How to Choose the Best Wheel Alignment Machine for Your Shop  Balancing the Details: The Role of Proper Tooling and Precise Mounting

Balancing the Details: The Role of Proper Tooling and Precise Mounting  8 Critical Factors to Consider Before Choosing Your ADAS Calibration Equipment

8 Critical Factors to Consider Before Choosing Your ADAS Calibration Equipment  What is Brake Assist?

What is Brake Assist?  The Ultimate Guide to OEM Certification

The Ultimate Guide to OEM Certification