OEM TRUSTED EQUIPMENT: BUICK | CADILLAC | CHEVROLET | CHRYSLER | DODGE | GENESIS | GMC | HYUNDAI | JEEP | KIA | RAM | TESLA | VOLVO

V2380 Imaging Diagnostic Wheel Alignment System

The John Bean® V2380 wheel aligner combines a classic post and beam design with the ultimate productivity-boosting technology to give shop owners the edge they need to perform efficient wheel alignment services.

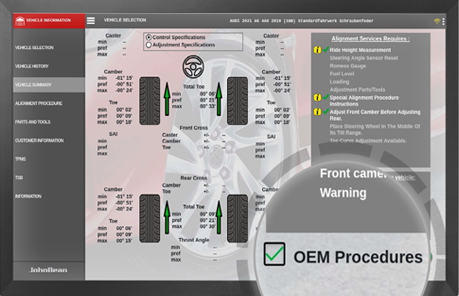

If your shop is looking to perform accurate alignment services at a fast pace, the John Bean V2380 is designed to get the job done with fast compensation and optimized alignment flow. Work quickly and accurately without slowing down critical alignment procedures by using our advanced notification system that instantly alerts the technician of suspension stress issues or other errors. Smart features like fast compensation and instant error notifications allow technicians to quickly move through optimized alignment steps.

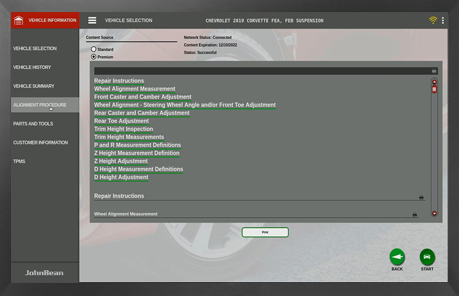

If technicians hit a snag while performing alignment services, Mitchell1® on-demand gives access to an extensive online, real-time database to work through nearly any alignment problem. Productivity boosting features like automatic camera tracking, EZ-Toe, and our exclusive AC400 wheel clamps help you drive more alignments through your shop.

VERSIONS

V2380 AC400 (EEWA545TBV3):

This version includes the AC400 wheel clamps.

V2380 AC200 (EEWA545THV3):

This version includes the AC200 wheel clamps.

Features

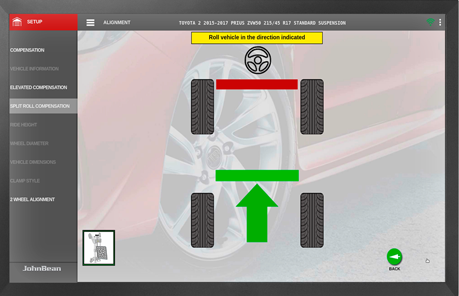

Streamline workflow with fast measurement compensation and an optimized alignment flow that enhances productivity by eliminating unnecessary steps in the alignment process.

Automatic camera tracking eliminates the need to readjust the cameras after raising the lift, it retains ultimate accuracy while moving the vehicle.

ADDITIONAL FEATURES

Eliminate manual data entry, speed up measuring, and increase accuracy using our specially designed, optional Ride Height Targets.

The optional kit allows you to mount the cross-beam to the cabinet for flexible installation and usage, enabling you to move the system around the shop freely and out of the way as needed.

MITCHELL1®

The aligner is network-connected, allowing technicians to access alignment repair information from Mitchell1 in just a few clicks.

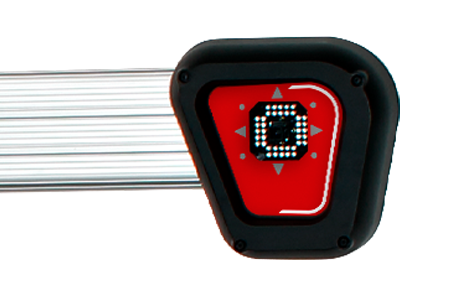

VODI™

Our exclusive Vehicle Orientation Directional Indicator (VODI) guides technicians through the measurement process when the monitor is not in view, with simple, easy-to-follow red and green LED lighting; reducing the amount of time spent walking back and forth from the vehicle to the aligner.

XD CAMERA TECHNOLOGY

OEM AFTERMARKET PROCEDURES

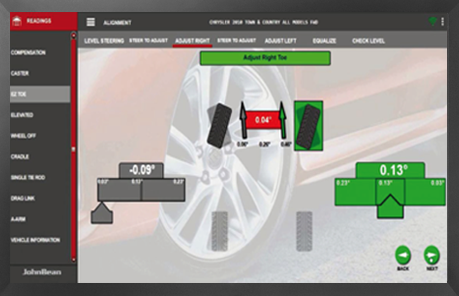

EZ-TOE

Our advanced software makes it easy to quickly and accurately measure toe angle, allowing technicians to turn the wheel to access challenging adjustment points without using a steering wheel holder.

CLOUD SERVICES

Easily share service reports with your customers via email or print from anywhere in the shop.

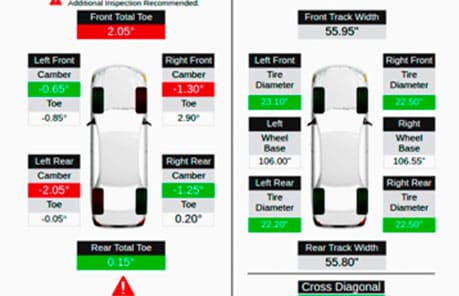

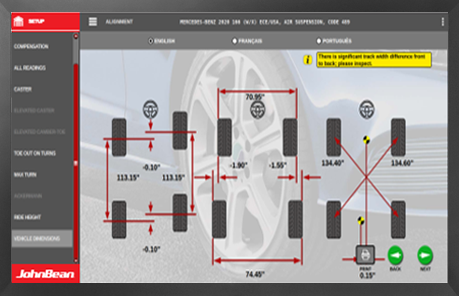

ADVANCED DIMENSIONS

Advanced vehicle dimensioning, including Cross Dimensions measurements to identify frame or structural damage before alignment adjustments are made, and Wheel Diameter to identify mismatched tire sizes, a potential cause of vehicle pulling and drive train damage.

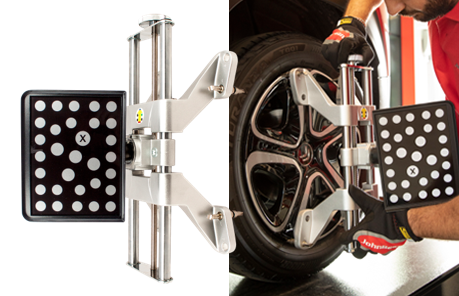

AC400 CLAMPS

The clamp attaches to the tire with optimal force without touching the rim; ensuring a safe, fast, and consistent clamping experience.

AC200 CLAMPS

Fast and easy to use with self-centering design, two-sided claws provide reliable clamping, even over hub caps.

ADJUSTMENTS

- EZ-Toe

- A-Arm

- Cradle

- Single Tie Rod

- Drag Link

- Toe Curve

- Elevated

- Help Videos

- Parts Calculator

- Parts & Tools

- Wheels Off

- Mitchell1® Adjust Assistance

MEASUREMENTS

- SAI

- Max Turn

- Toe Out On Turns

- Manual Ride Height

- TIP Target Ride Height

- Frame Angle

- ROMESS - OPTIONAL

- On-Demand Ride Height

ACCESSORIES

STANDARD

OPTIONAL