OEM TRUSTED EQUIPMENT: BUICK | CADILLAC | CHEVROLET | GMC

V2280 Imaging Diagnostic Wheel Alignment System

We’ve combined advanced wheel alignment technology with the easiest-to-use software interface on the John Bean® V2280 wheel aligner machine. Premium technology without the premium price.

The V2280 from John Bean allows shops to perform revenue-boosting alignment services without the need for extensive technician training or bulky equipment while ensuring customer satisfaction. Keep productivity high with our fast compensation feature that allows technicians to move through the alignment steps quickly and accurately. Automatic camera tracking removes the need for adjusting the beam height, saving valuable time. Our advanced notification system will compensate for almost any error made during the alignment in real-time, reducing the potential for errors by providing the necessary steps for corrective action if needed. Every step of our easy-to-use software was designed for efficiency and maximum output, allowing you to bring more revenue into your shop.

VERSIONS

V2280 LIFT (EEWAEU544TH4)

V2280 LIFT TT (EEWAEU544TH5)

Features

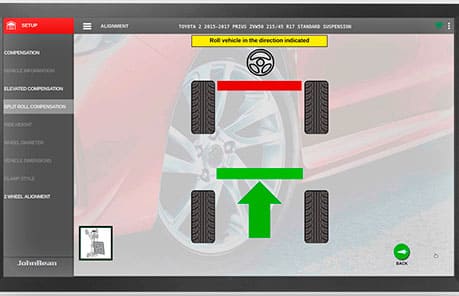

FAST COMPENSATION AND OPTIMISED ALIGNMENT FLOW

Streamline workflow with fast measurement compensation and an optimised alignment flow that enhances productivity by eliminating unnecessary steps in the alignment process.

ADVANCED NOTIFICATION SYSTEM

The advanced notification system provides critical information without slowing down the alignment process, automatically detecting and compensating suspension stress issues or environmental errors, only notifying the technician when necessary to provide additional information for corrective action.

AUTO CAMERA TRACKING

Automatic camera tracking eliminates the need to readjust the cameras after raising the lift, it retains ultimate accuracy while moving the vehicle.

RIDE HEIGHT

Eliminate manual data entry, speed up measuring, and increase accuracy using our specially designed, optional Ride Height Targets.

VIDEO: SEE IT IN ACTION

ADDITIONAL FEATURES

The optional mobility kit allows you to mount the cross-beam to the cabinet for flexible installation and usage, enabling you to move the system around the shop freely and out of the way as needed.

Easily share service reports with your customers via email or print from anywhere in the shop.

AC100 CLAMPS

Fast and easy to use with self-centring design, two-sided claws provide reliable clamping, even over hub caps.

ADJUSTMENTS

- EZ-Toe

- A-Arm

- Cradle

- Single Tie Rod

- Drag Link

- Elevated

- Help Videos

- Parts Calculator

- Parts & Tools

- Wheels Off

MEASUREMENTS

- SAI

- Max Turn

- Toe Out On Turns

- Manual Ride Height

- TIP Target Ride Height

- Frame Angle

- ROMESS - OPTIONAL

- On-Demand Ride Height

ACCESSORIES

STANDARD

OPTIONAL