OEM TRUSTED EQUIPMENT: BUICK | CADILLAC | CANOO | CHEVROLET | CHRYSLER | DODGE | GENESIS | GMC | HYUNDAI | JEEP | KIA | LEXUS | MITSUBISHI | RAM | SUBARU | TOYOTA | VOLVO

B2000P Automatic 3D Diagnostic Wheel Balancer

The John Bean® B2000P is a fully automatic diagnostic wheel balancing system that uses five high-resolution cameras to create a complete 3D mapping system of the rim and tire profile.

Our precision 3D runout measurements provide a commercial-grade level of surface measurement that can help technicians pinpoint balancing issues. A unique suite of diagnostic features such as tread depth analysis, tire wear-out prediction, uneven wear diagnosis, and automatic balance measurements help technicians identify weight and shape defects, flat spots, and incorrect bead seating. Our easy-to-read, intuitive software interface and touchscreen display provide all the necessary steps for technicians throughout the entire balancing process, boosting productivity and reducing potential operator error.

Not all tires are perfect, which can cause drivability issues such as vibration and pull. Our exclusive OptiLine™ technology analyzes the data of the complete wheelset and proposes the best placement for each wheel to compensate for tire pulling or steering wheel vibration problems. This feature provides accuracy on another level.

The John Bean B2000P is a world-class diagnostic wheel balancing system for professional shops. This technological powerhouse allows technicians to balance a wide variety of wheels with the highest degree of accuracy.

Features

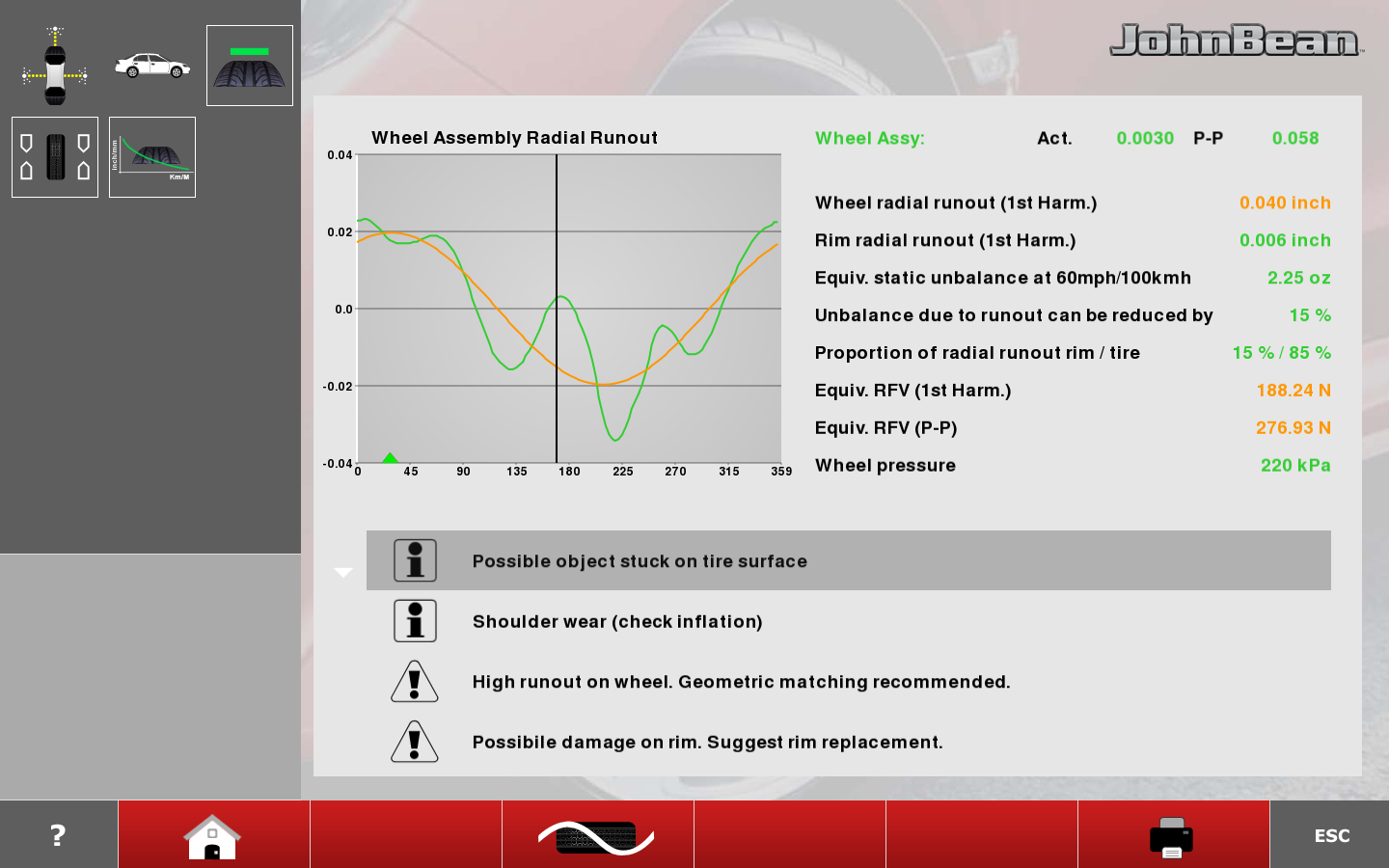

RUNOUT MEASUREMENTS

A 3D model of the tire and wheel allows for a complete diagnosis of the assembly uniformity and displays radial runout with peak-to-peak measurements from the first to the third harmonic.

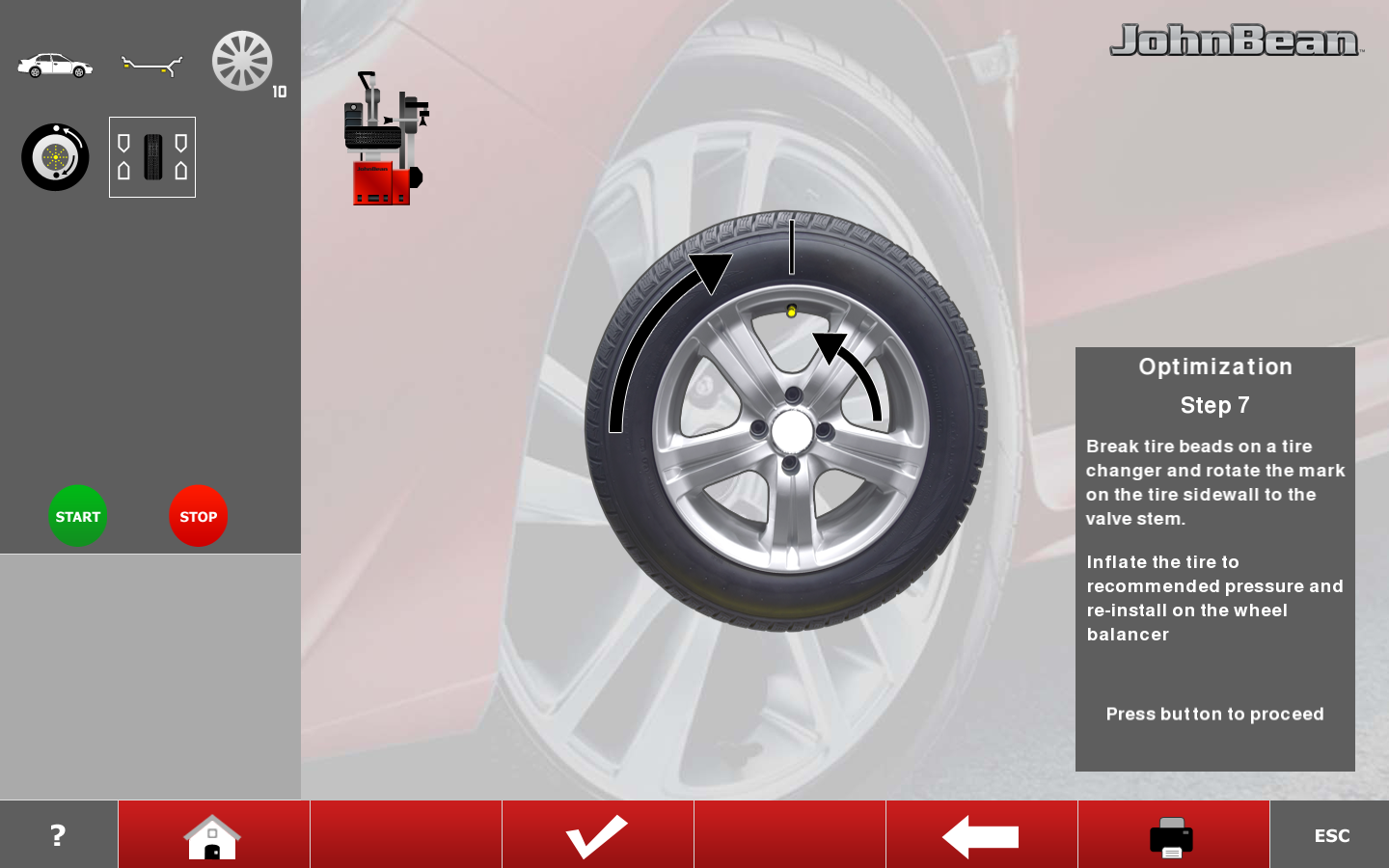

MATCH MOUNTING

Optimize the assembly of the tire on the rim improving the assembly roundness to reduce the shape vibrations.

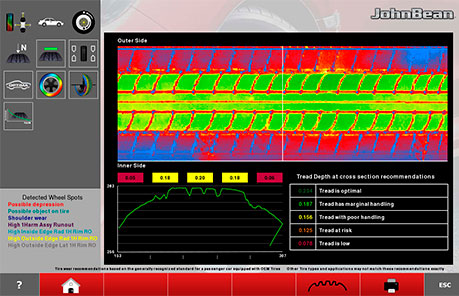

LASER 3D SURFACE MAPPING

Utilizes a high-resolution camera and laser-based technology to provide sidewall analysis, as well as depth, wear, and tire surface abnormalities that are displayed in an easy-to-read format.

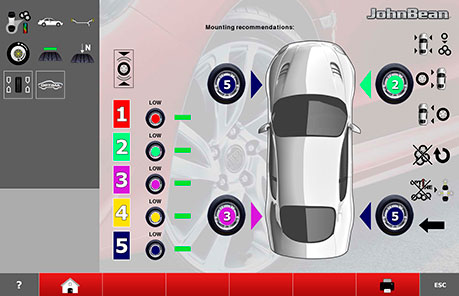

OPTILINE™ WHEEL SET OPTIMIZATION

Based on a predetermined set of criteria, OptiLine suggests the optimal location for each wheel to address any pull or vibration-related issues.

ADDITIONAL FEATURES

TOUCHSCREEN INTERFACE

Fast and intuitive interface with large digits, colored weight position indicators increase speed, ease-of-use, and ergonomics for the daily job.

EASYWEIGHT™

Take the guesswork out of weight placement; this pinpoint accurate system uses a laser to show the exact spot to place a weight to ensure precise balancing.

POWER CLAMP™

The electromechanical power clamping device always clamps the wheel accurately with a constant force and provides a reliable and consistent condition to assure accurate and repeatable measurements.

AUTOMATIC DATA ENTRY

No manual data entry is required; this machine automatically detects the wheel dimensions and selects the balancing mode, weight type, and weight position to speed up the balancing cycle time and minimize operational errors.

AUTOMATIC SPOKE DETECTION

The laser scanner automatically detects the number and position of rim spokes for the system to indicate weight placement behind wheel spokes and allow for split weights.

SPLIT WEIGHT MODE

This feature allows for accurate balancing with easy-to-follow manual procedures to hide the weights behind the spokes, preserving the wheel’s visual presentation.

STOP IN POSITION

Touch the screen to automatically rotate the wheel to the weight application position.

QUICKBAL™

Optimizes the number of revolutions according to each wheel’s specifications while always operating at maximum speed and reducing cycle time.

PRINTOUT

Reports can be printed through the local network or saved as a PDF to an external flash drive.

RIM LIGHTING

Bright LED lighting system that facilitates rim cleaning and aids in the weight positioning process.

EZ-COLLETS

The EZ-Collets mobile app lets technicians quickly find the best collet, flange, or quick plate for the job by selecting the vehicle and comparing the benefits of each specific tool.

TECH SPECS

Part Number

EEWB582AP230

Wheel Clamping

Power Clamp™

Automatic Rim Diameter Range

14″-26″ | 36-66cm

Automatic Rim Width Range

3″-15.8″ | 8-40cm

SAPE Rim Diameter Range

N/A

SAPE Rim Width Range

N/A

Manual Rim Diameter Range

8″-32″ | 20-81cm

Manual Rim Width Range

1″-20″ | 3-51cm

Max Wheel Diameter

44″ | 112cm

Max Wheel Weight

154 lbs. | 70 kg

Power Supply

230V 50/60Hz

Dimensions HxWxL

74″x48″x62″ | 189x123x158cm

Net Weight

342 lbs. | 155 kg

ACCESSORIES

STANDARD

OPTIONAL