OEM TRUSTED EQUIPMENT: GENESIS | HYUNDAI | MITSUBISHI | VOLVO

B9250 Heavy-Duty Wheel Balancer

Designed for maximum productivity in a compact footprint, the John Bean® B9250 is built to balance heavy-duty truck and tractor tyres with ease.

Equipped with semi-automatic parameter entry, the B9250 detects and inputs both offset and rim diameter gauge arm for maximum efficiency whereas rim width is entered manually. A built-in pneumatic loading device helps easily load heavy truck wheels and includes storage space for cones, centring stars, and wing nuts. The cabinet includes an easy-to-use digital display and storage space for 16 different wheel weights. The gauge arm guides users to the exact location for weight placement on the rim as the clamp holds the adhesive weight for placement. The B9250 includes an advanced alloy mode selection and spoke mode for optimum customised weight placement to accommodate the wide variety of heavy-duty wheel types on the road today. Advanced virtual plane imaging (VPI) removes the influence of outside variances to achieve a more accurate overall result.

Built with smart features designed to get the job done right, the B9250 from John Bean is the ultimate wheel balancer for heavy-duty applications.

Features

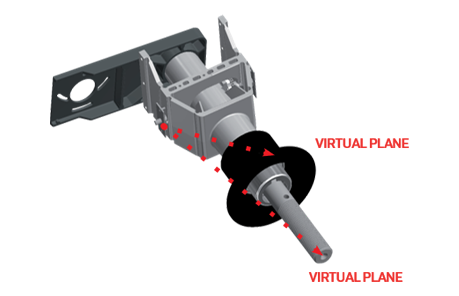

VIRTUAL PLANE IMAGING (VPI)

This patented technology, insensitive to ambient conditions, creates a virtual plane of the wheel between the sensors, eliminating external influences such as temperature variation or vibrations, ensuring the most accurate balancing results.

SEMI-AUTOMATIC PARAMETER ENTRY

Hand-operated gauge arm automatically detects and inputs rim offset and diameter.

ALLOY MODE SELECTION

A series of five different positions for customised weight placement, ideal for the wide variety of wheel designs on the market today.

GAUGE ARM WITH WEIGHT CLAMP

The gauge arm guides the technician to the correct position inside the rim and is equipped with a patented wheel weight clamp to hold the weight in the correct position during weight placement.

ADDITIONAL FEATURES

INTEGRATED DIGITAL LED DISPLAY

Ergonomic weight-tray-integrated touchpad operation with intuitive LED display.

SPLIT WEIGHT MODE

This feature allows for accurate balancing with easy-to-follow manual procedures to hide the weights behind the spokes, preserving the wheel’s visual presentation.

PNEUMATIC LOADING DEVICE

This lift helps facilitate the clamping of heavy truck wheels and offers ample storage space for cones, centring stars, and wing nuts.

TECH SPECS

Part Number

6027601

Wheel Clamping

Quick Nut

SAPE Rim Diameter Range

8″-26″ | 20-66cm

SAPE Rim Width Range

2″-20″ | 20-51cm

Max Wheel Diameter

51″ | 130cm

Max Wheel Weight

550 lbs. | 250 kg

Power Supply

230V 50/60Hz

Dimensions HxWxL

79″x57″x54″ | 201x145x137cm

Net Weight

595 lbs. | 270 kg

ACCESSORIES

STANDARD

OPTIONAL